News

Discover the Game-Changing Technology Transforming Woodworking Efficiency

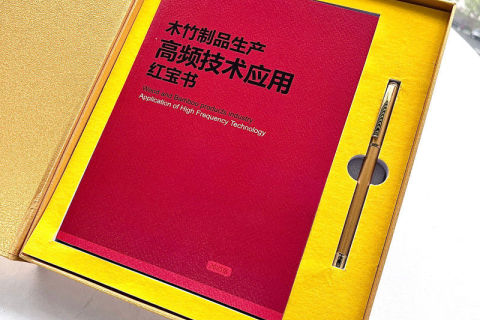

JYC proudly unveiled a new publication that promises to be a game-changer in the woodworking and bamboo processing industries.

At JYC, we specialize in delivering cutting-edge woodworking solutions that empower manufacturers to work smarter, faster, and with greater precision.

JYC recently wrapped up an incredibly productive week at the 55th China International Furniture Fair (Guangzhou)!

High Frequency Vacuum (HFV) drying has emerged as a transformative technology in the woodworking industry, offering significant advantages over traditional kiln drying.

In today’s competitive market, these challenges can be a major drag on your bottom line. The solution? High Frequency (HF) Wood Lamination.

JYC will be sharing more about High Frequency woodworking machines at the Dubai Wood Show on April 14-16!

In today’s competitive manufacturing landscape, efficiency is no longer a luxury – it’s a necessity.

For decades, certain curved wood designs have remained perennially popular, gracing chairs, tables, and other furniture pieces with their timeless elegance.