- Home

- >

News

Welcome to visit our booth!

We cordially invite you to visit our booth to explore our latest machinery and innovations.

What can increase the efficiency of the factory?

What Is High Frequency Wood Frame Assembly Machine? In the realm of woodworking and frame assembly, efficiency and quality are paramount. Traditional methods often involve time-consuming processes like nailing, which not only slow down production but can also compromise the structural integrity of the final product. However, modern technologies such as high frequency wood frame assembly machine and quick-curing adhesives have revolutionized the industry by significantly enhancing both the speed and quality of assembling wooden frames. High Frequency Wood Frame Assembly Machine HF wood frame assembly machines utilize high frequency heating glues to rapidly bond wooden pieces together. Unlike conventional methods that rely on mechanical fasteners, such as nails or screws, radio frequency wood frame assembly machines create strong and durable bonds within seconds. This not only eliminates the need for nails but also ensures a cleaner finish without unsightly puncture marks. As a result, artisans and manufacturers can produce frames, boxes, and other wooden structures more efficiently and with enhanced structural integrity. By eliminating the waiting time required for traditional wood glues to dry, instant adhesives allow for immediate handling of assembled frames. This accelerates production timelines and reduces overall manufacturing costs by optimizing workflow and minimizing downtime. Benefits for Artisans and Manufacturers The integration of high-frequency frame joiners and instant adhesives offers numerous benefits to both artisans and large-scale manufacturers. Artisans specializing in handcrafted frames can maintain high standards of craftsmanship while significantly increasing their production capacity. For manufacturers, the adoption of these technologies translates into higher throughput and improved product consistency, meeting the demands of a competitive market. Conclusion In conclusion, the combination of RF wood frame assembly machine and quick-curing adhesives represents a significant advancement in the woodworking and frame assembly industry. These technologies not only streamline production processes but also elevate the overall quality of wooden frames and related products. By eliminating the drawbacks of traditional assembly methods, artisans and manufacturers alike can achieve greater efficiency, improved product quality, and enhanced profitability.

A good environment can make manufacturing better!

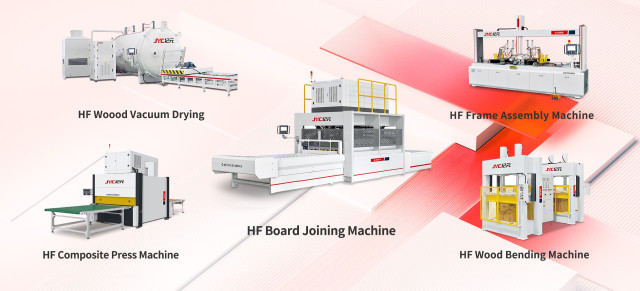

As a leading company in the field of high frequency application technology, JYC High Frequency will continue to lead this wave of home manufacturing efficiency revolution with its solid technological accumulation.

Let's see JYC do what at the end of 2023, and the beginning of 2024

When it comes to kitchen cabinet doors, there is a wide variety of styles available worldwide. These styles differ in design, material, and functionality, allowing homeowners to choose the perfect option to suit their taste and kitchen aesthetics.

I can tell you seriously and responsibly that the answer is no. The high-frequency frequencies emitted by high-frequency woodworking machinery will not cause harm to the human body.

he biggest difference is that manual production cannot be mass-produced. Manual production requires a lot of time, effort, and money.

The high-frequency wood frame assembly machine is a game-changer for woodworking businesses. It saves time and labor costs while ensuring high-quality wood frames that meet industry standards. Its precision, efficiency, and versatility make it a valuable investment for any woodworking operation.