Application of High Frequency Technology in Solid Wood Material Preparation

2024-06-12 16:38Classic Case Sharing

A Certain Teak Furniture Brand

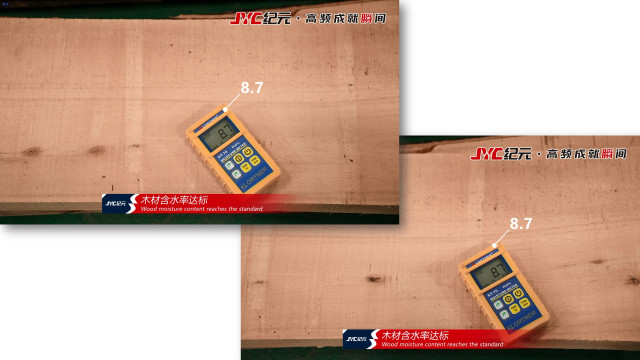

As a representative brand of high quality teak furniture, they have been deeply loved by the market with their high quality materials and craftsmanship. They paid attention to the high frequency wood vacuum drying solution provided by JYC, which precisely met their real needs with its uniform drying effect, good drying quality, and extremely fast drying efficiency.

Dongguan Home Furnishing Brand Manufacturer

A world-class home furnishing brand manufacturer located in Dongguan, engaged in activities including solid wood veneer, solid wood painting, furniture manufacturing, etc., with production capacity, equipment, and technology at the industry-leading level. JYC's high frequency fully automatic edge glued wood board joining line helped them in the processing of solid wood veneer material, connecting the four-sided planing and wood board joining two links, and achieving full automation of the wood board joining process.

An International Home Furnishing Brand in East China

The products of this brand cover three major furniture fields: plastic, solid wood, and soft furniture, maintaining nearly 1500 different styles of plastic chairs, wooden chairs, bar chairs, soft package chairs, metal chairs, sofas, and other products, which are highly praised by customers at home and abroad. In 2019, when they decided to independently produce bentwood structural components, they firmly chose JYC's radio frequency bentwood press. During the cooperation period, they continued to increase the number of equipment.

The New Value Brought by JYC's High Frequency Technology Application to Solid Wood Material Preparation

Solid wood material preparation is usually a larger area, more labor-intensive, and longer production cycle process in processing enterprises. The introduction of high frequency technology equipment has changed the inefficient and low-automation processing mode with a large amount of manual participation. It not only solves the major pain points in the early material preparation process but also improves product quality and continuously empowers subsequent processing. This has significant implications for the overall production efficiency, cost optimization, and enhancement of enterprises.

|HF Technology |Traditional Process

--------------------------------------------

Yield | ********* | *****

Processing Cycle| ** | *********

Input Costs | *** | *******

Product Quality | ***** | ***

Conclusion

Solid wood material preparation is an extremely important front-end task in home furnishing manufacturing production. To improve the production efficiency and quality of solid wood material preparation, the introduction of high frequency technology equipment will bring about a revolutionary upgrade. Choose high frequency, trust JYC! JYC's mature HF technology should help you achieve upgrades in various process requirements in the material preparation process!