Are High Frequency Wood Laminating Machines the Secret to Perfect Wood Flooring?

2024-10-23 15:01The Beauty and Durability of Wood Flooring

Wood flooring has long been a symbol of elegance and sophistication in home design. Its natural beauty, combined with its durability and versatility, makes it a popular choice for homeowners and interior designers alike. Wood floors can enhance the aesthetic appeal of any room, providing a warm and inviting atmosphere that is unparalleled by other flooring options. Additionally, wood floors are highly durable and can last for decades with proper care and maintenance.

The Role of High Frequency Wood Laminating Machines in Wood Flooring Production

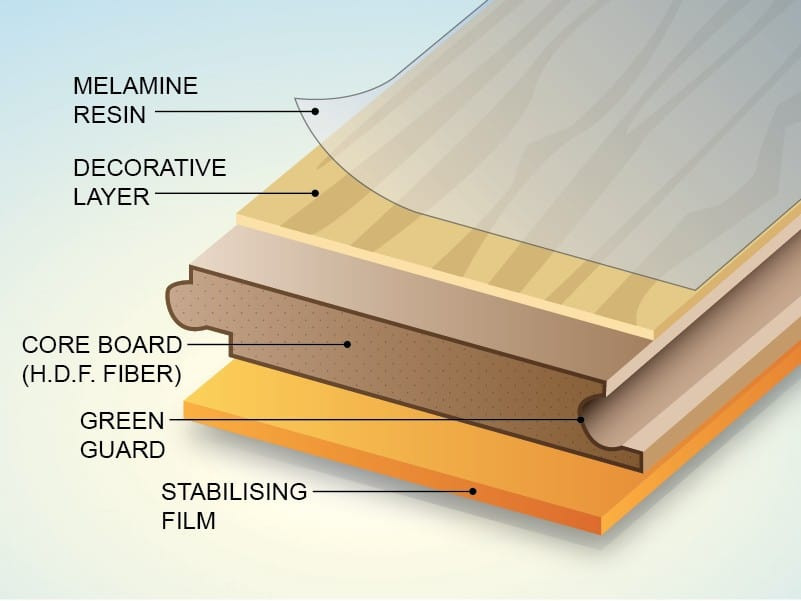

Wood flooring typically consists of multiple layers of wood, each with its unique properties and functions. These layers are bonded together using adhesives to create a sturdy and aesthetically pleasing final product. Traditionally, this bonding process involved the use of heat presses, which could be time-consuming and sometimes compromise the quality of the bond.

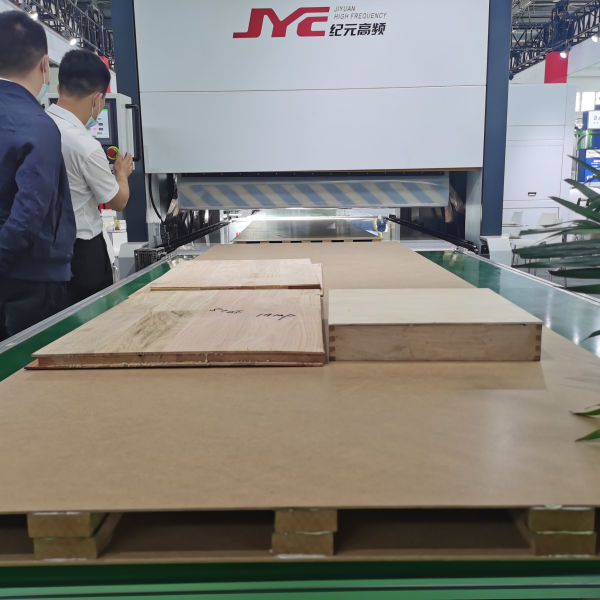

High frequency wood laminating machines have changed this paradigm. These machines use high frequency electromagnetic waves to cure the adhesive that bonds the layers of wood together. This process is much faster and more efficient than traditional heat press methods. The HF waves penetrate deep into the wood, ensuring a strong and durable bond without the risk of burning or damaging the material.

Benefits of HF Wood Laminating Machines for Wood Flooring

Speed and Efficiency: Radio frequency wood laminating machines can significantly reduce the production time of wood flooring. This increased efficiency allows manufacturers to meet the growing demand for wood floors without compromising on quality. For example, a single machine can bond multiple layers of wood in a fraction of the time it would take with traditional methods.

Quality Assurance: The HF bonding process ensures a strong and uniform bond between layers of wood. This enhances the overall durability and stability of the flooring, making it more resistant to wear and tear. When it comes to wood floors, a strong bond is crucial to prevent delamination, which can lead to structural issues and an unsightly appearance.

Environmental Friendliness: RF wood laminating machines require less energy compared to traditional heat press methods. Additionally, the process does not produce harmful emissions, making it a more eco-friendly option. This is particularly important in the wood flooring industry, where sustainability is a growing concern.

Versatility: These machines can be used to produce a wide range of wood flooring products, from solid wood planks to engineered wood and laminate flooring. This versatility makes them an invaluable asset in the wood flooring industry, allowing manufacturers to cater to diverse customer preferences and needs.

The Impact on the Wood Flooring Industry

The introduction of high frequency wood laminated machines has had a profound impact on the wood flooring industry. Manufacturers can now produce high-quality wood flooring at a faster pace and with greater efficiency. This has led to a significant increase in the availability of wood flooring options, making it more accessible and affordable for homeowners.

With the advent of radio frequency wood laminating machines, the production of wood flooring has reached new heights of efficiency and quality. These machines play a crucial role in ensuring that the final product meets the highest standards of durability and aesthetic appeal. More and more wood floor manufacturers are paying attention to these machines which can help to improve the quality of the products, also it great help for the business.