Creating the Ideal Choice for Solid Wood Plywood - JYC High Frequency Laminating Press

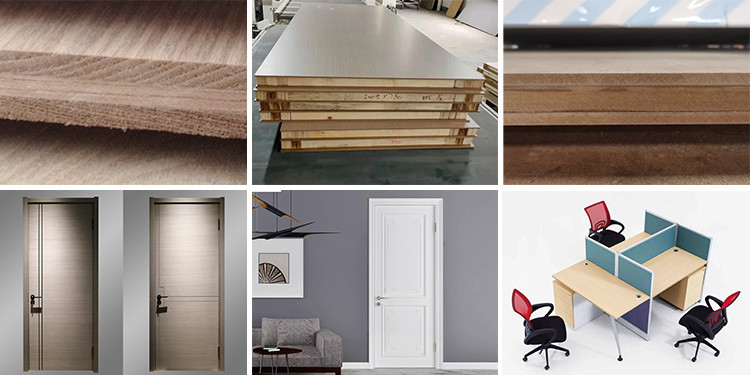

2023-11-21 15:53High frequency wood laminating presses offer numerous advantages in the manufacturing of solid wood plywood, including strong bonding strength, increased production efficiency, wide adaptability, excellent surface quality, and environmental friendliness. Choosing a high frequency press not only enhances product quality and production efficiency for furniture manufacturers but also meets consumer demands for high-quality and eco-friendly furniture, injecting new energy into the furniture industry's development.

In the field of furniture manufacturing, radio frequency laminating presses have become the preferred choice for the lamination process of solid wood plywood. This article will introduce several key advantages and analyze why hf wood laminating machines are the ideal choice for furniture manufacturers in the production of solid wood plywood.

Strong Bonding Strength:

High frequency laminating machines utilize uniform penetration of high frequency electric fields to generate heat in the lamination process, activating the adhesive from the inside out. This process achieves strong bonding between material layers, resulting in products with excellent structural stability, resistance to warping, and prevention of delamination.

Increased Production Efficiency:

Radio frequency wood laminating machines significantly improve production efficiency in furniture manufacturing. The rapid heating and curing process greatly shortened the production cycle, allowing furniture manufacturers to increase output and meet tight delivery schedules. This high efficiency not only saves costs but also enhances the productivity of furniture factories.

Wide Adaptability:

High frequency wood laminating presses can be used with various wood materials. Whether it is solid wood, plywood, or multi-layered boards, hf wood laminating machine effectively performs the lamination process, helping furniture manufacturers diversify their product lines to meet the needs of different consumers.

Excellent Surface Quality:

The lamination process of rf wood laminating machine ensures flat and flawless product surfaces, enhancing the aesthetics of furniture products. High-quality surface treatment enhances the overall aesthetics and value of furniture, making it more attractive.

Environmental Friendliness:

High frequency wood board laminating machines reduce the amount of adhesive used in the lamination process, reducing their impact on the environment. Additionally, the high frequency lamination process does not require the use of solvents and other chemicals, making the manufacturing process more environmentally friendly. Choosing a high frequency press not only provides high-quality products but also actively responds to environmental awareness and meets consumer demands for eco-friendly furniture.

Conclusion:

High frequency wood laminating presses offer numerous advantages in the manufacturing of solid wood plywood, including strong bonding strength, increased production efficiency, wide adaptability, excellent surface quality, and environmental friendliness. Choosing a radio frequency wood laminating machine not only enhances product quality and production efficiency for furniture manufacturers but also meets consumer demands for high-quality and eco-friendly furniture, injecting new energy into the furniture industry's development.