How do you make wood dry faster?

2023-09-01 17:28Currently, the commonly used wood drying techniques worldwide include:

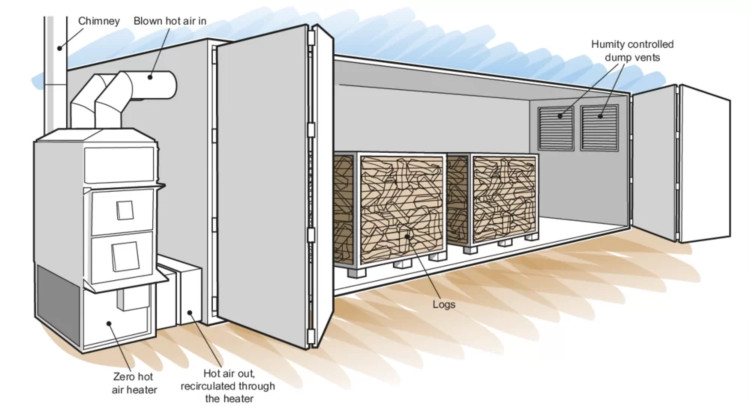

Hot air drying: This traditional method accelerates moisture evaporation by conducting, convecting, or radiating heat onto the wood. It finds extensive applications in industrial and commercial sectors.

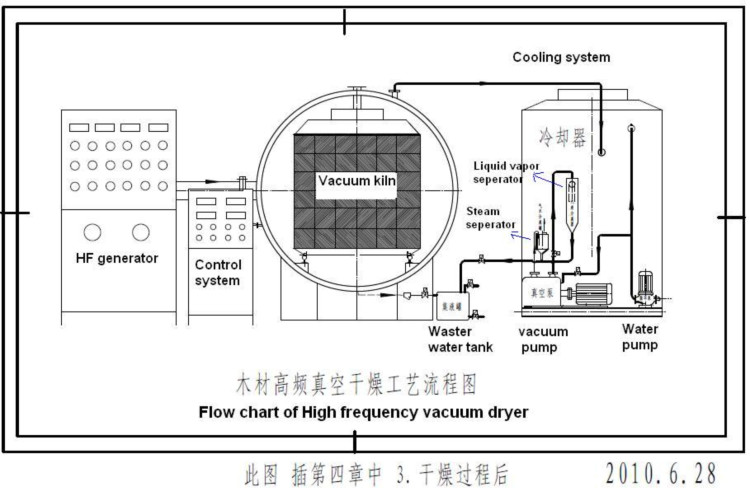

Vacuum drying: By applying heat in a vacuum environment, moisture in the wood is converted into vapor, which is then extracted through vacuum extraction, enabling rapid drying. This method effectively reduces drying time and minimizes wood cracking issues.

Microwave drying: It utilizes microwave radiation to heat the interior of the wood, causing water molecules to vibrate and evaporate quickly. Microwave drying is known for its speed, uniformity, and energy efficiency, making it suitable for various wood types.

High-frequency drying: Wood is heated rapidly and moisture evaporates quickly using a high-frequency electric field. High-frequency drying is characterized by its speed, energy efficiency, and environmental friendliness, making it widely used in the wood processing industry.

These wood drying techniques have their respective advantages and applicability in different industries and regions. The selection of an appropriate drying method depends on factors such as wood type, size, target moisture content, and production requirements.

These wood drying techniques have the following specific advantages and applicability in different application areas:

Hot air drying:

Suitable for various wood types and sizes.

Widely used in industrial and commercial sectors.

Enables precise drying by controlling temperature and humidity.

Vacuum drying:

Enables rapid drying, reducing drying time.

Effectively reduces wood cracking and warping issues.

Suitable for high-value and special types of wood.

Microwave drying:

Quick and uniform drying, saving time.

Allows control of temperature and humidity during drying.

Particularly effective for thick wood and wood with high moisture content.

High-frequency drying:

Fast and energy-efficient wood drying.

Temperature and humidity can be controlled during the drying process.

Performs well with thin wood and wood with special requirements.

The advantages and applicability of each drying method may vary in specific application areas. Therefore, when selecting a wood drying method, it is important to consider the characteristics of the wood, target moisture content, size requirements, and production needs. A comprehensive evaluation of the advantages and limitations of each technique should be conducted to determine the most suitable drying method.

Our machine is combined with high frequency and vacuum technology, which means it also combines these advantages. JYC high frequency vacuum wood drying machine can balance efficiency and quality ensuring fast drying of wood also without discoloration and cracking after drying!