How High Frequency Generators Are Redefining Wood Processing

2024-12-25 15:43The advancement of modern woodworking is intricately tied to the development of efficient and precise heating technologies. While traditional methods relying on conduction or convection heating have served the industry for decades, the limitations of these techniques, particularly concerning speed, control, and uniformity, have long been recognized. This has led to the emergence of high frequency (HF) generators as the fundamental power source for a new era in wood processing.

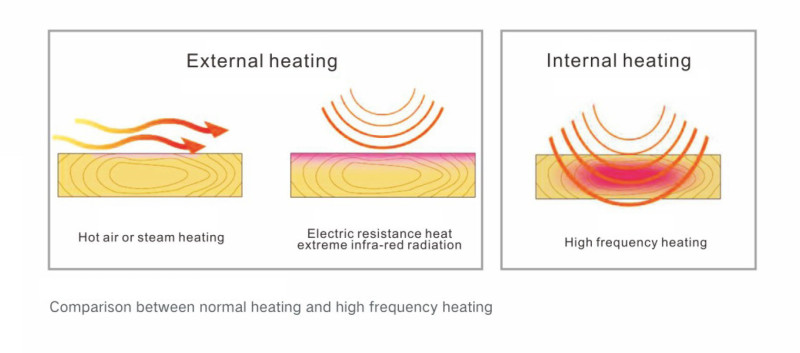

This article delves into the core function of HF generators, explaining their operation, advantages, and their crucial role as the driving force behind advanced woodworking machinery. Unlike conventional heating which relies on heating surfaces or air, HF generators utilize electromagnetic waves within the radio frequency spectrum. This energy is precisely targeted to the material, causing rapid molecular agitation and directly generating heat within the wood or adhesive, with limited impact on the surrounding environment. The key advantage of this method lies in the fact that heat is generated within the targeted material itself. This is in stark contrast to traditional methods where heat is transferred to the material through the environment, leading to heat losses and slower heating times.

The efficiency of high frequency heating is also significantly higher than traditional techniques. Due to the elimination of heat transfer inefficiencies and the rapid generation of heat, HF generators typically consume less energy to achieve the same results, often showing energy savings of 20-40% compared to conventional methods. This leads to lower operating costs and a reduced environmental impact. Further studies demonstrate that Radio Frequency energy application reduces heat-up times by up to 80%, resulting in significantly reduced cycle times.

Beyond efficiency, the precision and control afforded by RF generators are equally critical. The power output and frequency can be precisely adjusted, enabling the application of targeted heating to specific areas of a workpiece. This targeted control minimizes the risk of overheating, material degradation, and warping, which are common issues with conventional heating. This precise control ensures that the heat application is uniform, which leads to more predictable and consistent results. This uniformity is crucial for applications like laminating, bonding, and drying, where variations in heat application can directly compromise the final product.

The versatility of HF technology makes it the cornerstone of a wide array of innovative woodworking machinery. From high-speed board jointers and precision bending machines to rapid wood drying systems and high-throughput laminators, HF generators provide the necessary power to drive these modern processes. By enabling greater control, speed, and efficiency, HF technology is transforming the way woodworking is approached, unlocking higher levels of productivity and craftsmanship. High Frequency Generators are not just powering machines; they are powering progress in the woodworking industry, allowing for more precise, efficient, and innovative manufacturing processes. Understanding the capabilities of this technology is crucial for any professional seeking to remain competitive in the rapidly evolving world of woodworking.