The Power of High Frequency Generators in Woodworking

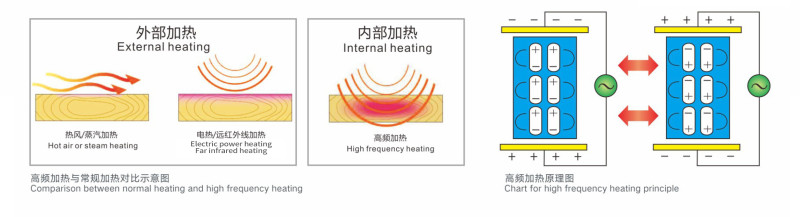

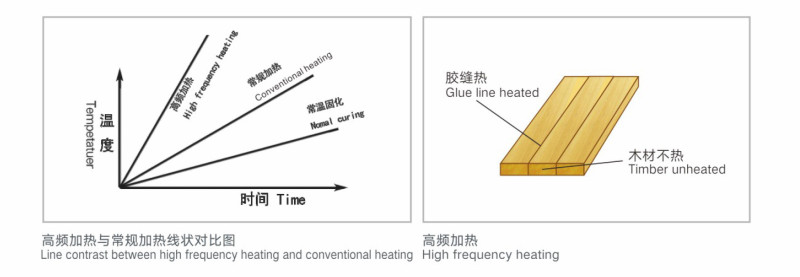

2024-10-03 16:01The working principle of high frequency generators involves producing electromagnetic waves, typically in the range of 1 to 30 MHz. These waves generate heat within the materials—usually wood and adhesives—by exciting their molecules. When applied, the heat quickly cures adhesives or dries materials, allowing for rapid bonding and processing. This method ensures even heating and minimizes thermal damage, resulting in strong, durable joints and finishes.

High frequency generators are revolutionizing woodworking by enhancing efficiency and precision in processes like drying, joining, bending, and laminating. These HF generators produce electromagnetic waves that provide rapid heating, allowing for quicker curing of adhesives and seamless bonding of materials. This technology not only reduces production time but also minimizes energy consumption, making it a sustainable choice for modern woodshops. By investing in a radio frequency generator, woodworkers can achieve ultimate precision in their projects while maximizing productivity. As the demand for high quality, durable wood products rises, incorporating this innovative equipment can give businesses a competitive edge in the market.