The Role of High Frequency Wood Drying Machines in Quality Control

2024-02-13 11:53Ensuring consistent and high quality wood products is a crucial aspectIntroduction:

High frequency vacuum wood drying machines have revolutionized the process of drying lumber, offering numerous advantages over traditional drying methods. In this article, we will discuss the benefits of using HF vacuum wood dryer and how they have improved the efficiency and quality of the wood drying process.

Faster Drying Times:

One of the significant advantages of radio frequency wood drying machines is their ability to significantly reduce drying times compared to conventional methods. The high frequency electromagnetic waves penetrate the wood and generate heat directly within the material, resulting in accelerated moisture evaporation. This faster drying process allows for increased production rates and shorter lead times, benefiting both manufacturers and customers.

Improved Wood Quality:

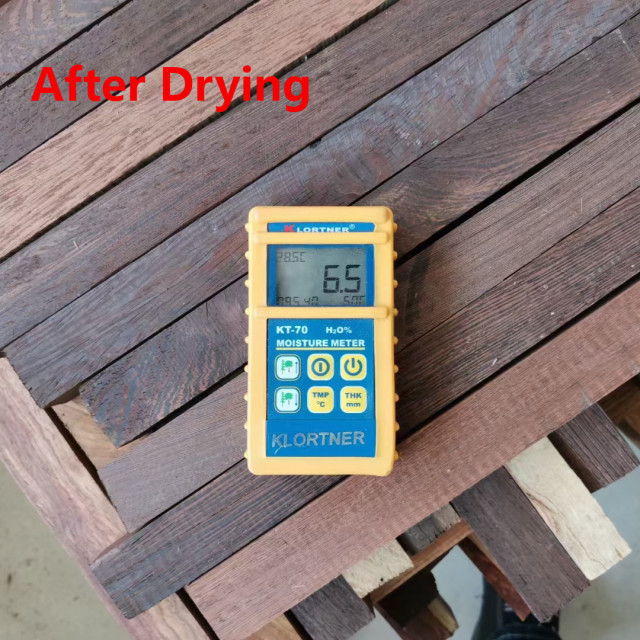

High frequency vacuum wood drying equipments provide precise control over the drying process, leading to improved wood quality. The uniform heat distribution and controlled moisture removal prevent the development of defects such as warping, checking, and splitting. This results in higher-quality lumber with reduced waste and improved stability, making it ideal for applications that require dimensional accuracy and structural integrity.

Energy Efficiency:

RF vacuum wood drying machines are more energy-efficient compared to conventional kiln drying methods. The targeted heating process ensures that energy is used efficiently without wasting heat on the surrounding environment. Additionally, the faster drying times contribute to energy savings by reducing the overall drying cycle. This energy efficiency not only reduces operational costs but also promotes sustainable practices in the woodworking industry.

Versatility and Adaptability:

HF timber drying machines are versatile and adaptable to various wood species, thicknesses, and shapes. The machines can handle a wide range of wood products, from small boards to large beams, with consistent and reliable results. This versatility allows manufacturers to dry different types of wood simultaneously, optimizing production efficiency and flexibility.

Reduced Wood Degradation:

Traditional drying methods, such as air drying or kiln drying, can lead to wood degradation and loss of natural color. HF vacuum wood drying machines minimize these issues by quickly removing moisture and reducing the exposure time to high temperatures. This results in less discoloration and minimal degradation, preserving the natural beauty and integrity of the wood.

High frequency wood drying machines offer several advantages over conventional drying methods. From faster drying times and improved wood quality to energy efficiency and adaptability, these machines have transformed the wood drying process. By utilizing high frequency electromagnetic waves, manufacturers can achieve efficient and high quality wood drying, enhancing productivity and reducing waste in the woodworking industry. The combination of these technologies contributes to the overall excellence of wood products and promotes innovation in the woodworking industry.