Unveiling: Applications of Honeycomb Composite Materials in Furniture Manufacturing!

2023-07-20 21:30Exploration:

What is honeycomb composite material?

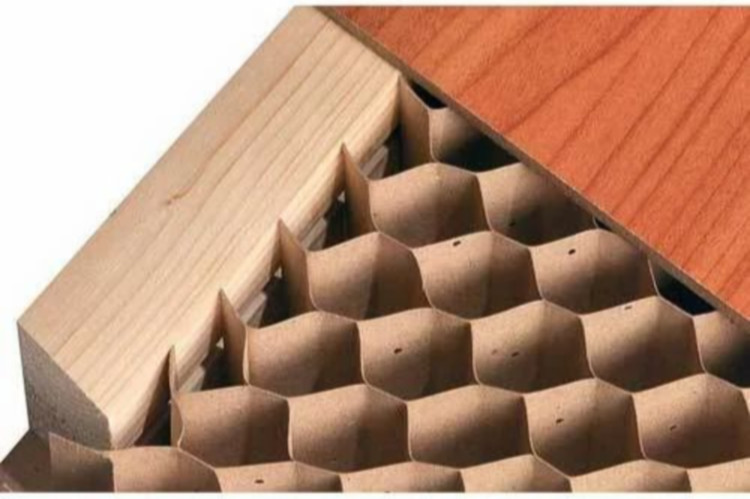

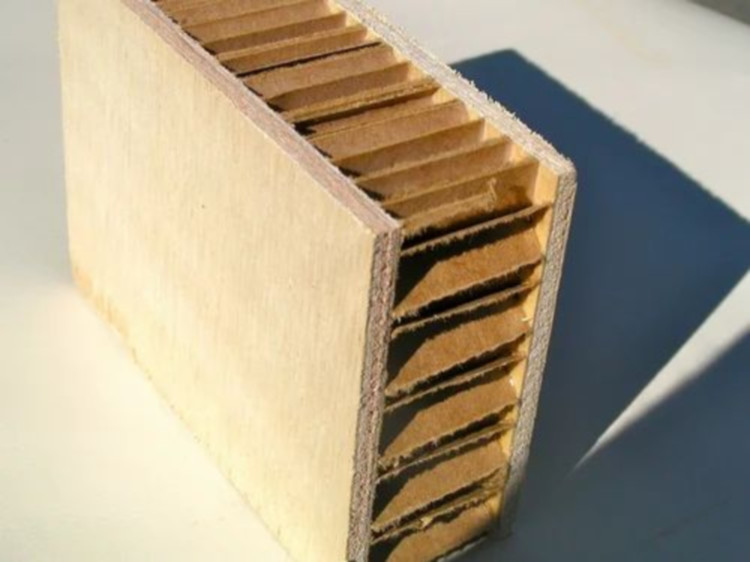

Honeycomb composite material is an environmentally-friendly new type of material made up of two thin sheets on top and bottom, a hexagonal honeycomb-shaped paper core in the middle, and glued together with adhesive.

There are two common types of honeycomb composite materials: honeycomb paperboard and honeycomb aluminum board. Although the materials are different, both have the characteristics of light weight, high strength, high rigidity, shock and insulation, and are widely used in the construction industry, furniture manufacturing, packaging, transportation and other fields.

Honeycomb composite materials have many advantages.

In the field of furniture manufacturing, honeycomb composite materials are often used in the form of honeycomb composite panels. Honeycomb composite panels are composite boards made of thin artificial boards and honeycomb paper cores that are glued and pressed together. As a sandwich material, the honeycomb paper core material only accounts for about 1% to 5% of the solid material, and 1 ton of honeycomb paper composite material can replace 30 to 50 cubic meters of wood.

Although honeycomb composite panels are lightweight, they have outstanding advantages:

#They have a unique mechanical structure, are lightweight, have high strength, and can bear heavy loads.

#They have high rigidity and are not easily deformed.

#They have strong sound insulation and seismic resistance and are moisture-proof and fire-resistant.

#They are easy to install and maintain.

#They greatly reduce building loads and costs.

#The surface paint is durable, weather-resistant, and resistant to chemical corrosion.

#They are luxurious, beautiful, and durable.

#They do not pollute the environment and can be recycled.

Of course, honeycomb composite materials are not without their drawbacks. For example, the adhesive effect of aluminum honeycomb panels can be affected by oil stains, dirt, and loose oxide layer naturally formed on the surface of the aluminum sheet, which requires cleaning and pre-treatment before use. However, despite its flaws, according to Mr. Yin, the general manager of Feibao Manufacturing, honeycomb aluminum panels have been widely used in many fields such as home furnishing manufacturing due to their huge advantages.

How to use?

Applications of honeycomb composite materials in the furniture manufacturing industry.

Using honeycomb composite materials can not only reduce production costs and save the amount of wood used but can also effectively solve the problem of deformation of artificial boards, making it highly praised by home furnishing companies.

Honeycomb composite materials are excellent materials for producing panel furniture, especially in products such as panels, top plates, partitions, bottom plates, door panels, and some decorative products with a thickness greater than 18 mm. Additionally, they are also used in the production of home furnishing products such as dining tables, coffee tables, TV cabinets, furniture legs, etc.

How to make?

JYC High frequency wood laminating machine is the best choose!

With its characteristic of "uniform heating with low-temperature penetration," honeycomb composite materials are favored by major wooden door companies and composite board manufacturers and have received high praise for their "cold-pressed quality and hot-pressed efficiency."

1. High-frequency electric field selective heating increases working efficiency.

2. Heating efficiency is not affected by the thickness of the surface panel.

3. Uniform low-temperature heating helps prevent workpiece deformation.

4. High level of automation allows for the adjustment of production methods according to actual site and process requirements.

Different product processes can be accommodated with the option for single-sided or double-sided selective heating and can be freely switched.

It can be used as a standalone machine or linked to a production line with through-feed and discharge capabilities.

It only requires one-time heating without the need for segmenting, and has a small footprint.

5. Low radiation and multiple protection measures are in place.

6. Versatility, with wide-ranging applications.

The JYC Radio Frequency Wood Laminating Press is one such machine that has a wide range of applications. It can be used for the composite of wood veneers (sheets) other than those less than 2mm and greater than 12mm, as well as for paint-free wooden doors, bamboo and wood multi-layer products, office furniture tabletops, and bamboo and wood packaging box panels.

Check the video, to know more about how to make honeycomb panels with JYC high-frequency wood laminating machine!