What Can Make The Bentwood More Perfect? The Answer is......

2024-02-24 16:251. Production process of bending wood furniture

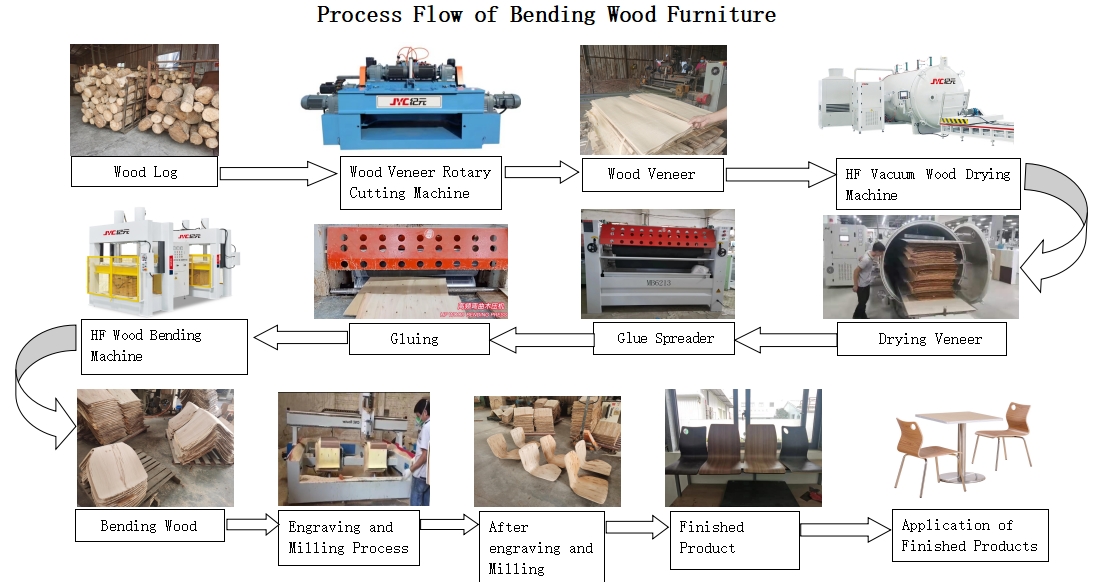

First, the logs are processed by a veneer rotary cutter to cut them into thin veneers. To ensure the quality of the veneer, it will be subjected to high frequency wood vacuum drying to make the moisture content reach the standard.

Next, the glue applicator evenly applies glue to the wood veneer, preparing it to enter the high frequency bending wood press for shaping. In a press, the veneer is bent into the desired shape under the appropriate pressure and temperature, forming bentwood.

After that, the bentwood is finely processed through routing and milling, followed by quality inspection and trimming.

Finally, after polishing, painting, and other treatments, a beautifully finished piece of bentwood furniture is born. The entire process ensures the quality and uniqueness of each piece of furniture, providing the market with unique and high-quality bent wood furniture products.

2. A powerful tool for efficiently producing various curved wood products

At present, JYC High Frequency machines mainly provide complete solutions for the drying and bending of wood veneer. Now we will mainly introduce our high frequency bending wood press machine. If you use the JYC HF wood bending press series, not only can you easily realize bending woodworking For high-quality mass production of parts, it is also possible to replace the production of curved products with other curvatures and other sizes by replacing low-cost wooden molds. The processing range is very wide, ranging from musical instrument boxes and small coffee tables to large chairs, curved wall panels, large curved art workpieces, etc.

3. One-direction press and three-direction press to meet diverse wood bending needs

JYC radio frequency bending wood presses can also be divided into two categories: One-direction bending wood presses and three-direction bending wood presses according to the different curvature of the product.

The One-direction bending wood press is mainly used to bend wood in a single direction, causing the wood to gradually deform to achieve the required arc. It has a simple structure and is easy to operate.

Compared with the One-direction bending wood press, the three-direction bending wood press can bend the wood in three directions, thereby better meeting various complex processing needs. The three-direction bending wood press uses multiple pressure devices and adjustable molds to press the wood in multiple directions at the same time to achieve precise arc and shape control.

4. Advantages of JYC high frequency bending wood press machine

First, it can quickly solidify the glue without rebounding;

Second, in the configuration of one belt and two machines, all machines work alternately, and the efficiency is increased by more than 50%;

Third, the cost of grinding tools is low and orders can be received flexibly;

Fourth, low energy consumption, environmentally friendly, and safe;

Fifth, it has obtained multiple patents and CE certification;

JYC's high frequency bending wood machine greatly improves the production efficiency of curved furniture and other household wood products, reduces labor costs, makes the products more stable and of better quality, and can better meet the needs of high-end customization, whole-house customization, and door and wall cabinets. Integrated market demand adds icing on the cake to your business expansion.