What is a high frequency generator?

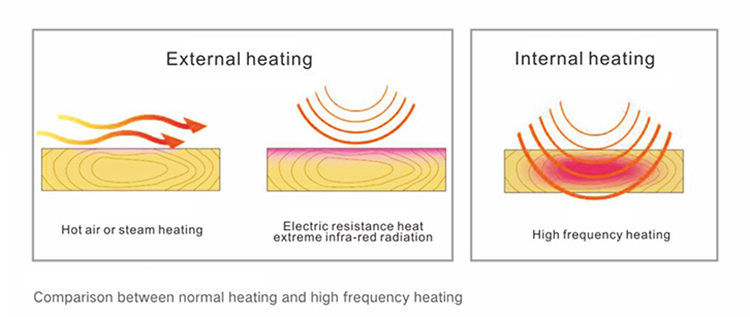

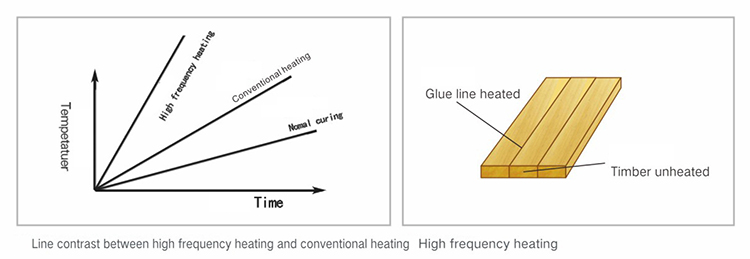

2023-08-04 17:01High-frequency heating uses the energy of high-frequency oscillating electric fields to heat dielectric materials. Under the action of the high-frequency electric field, the high-frequency alternating displacement of the positive and negative charges in the molecule and the atom of the dielectric material will be produced, and the thermal motion of the molecule and the atom will be intensified, thus the material will be heated. Heat is generated in the heated material, so the heating speed is fast, the heating time is short, and the thermal efficiency is high.

High frequency generators can be used in many fields, so you might hear about high frequency generators. But high frequency generators used in woodworking machines can play a role that cannot be ignored.

Characteristics of High-Frequency Dielectric Heating:

1. Fast heating speed and high efficiency: In the conduction heating method, heat is transmitted from the outside to the inside of the heated object, and the thickness of the material determines the time required. High-frequency heating generates heat within the dielectric material itself through a high-frequency electric field and can heat the interior in a very short time, without considering the time required for heat transfer. Compared with conduction heating, the effect of heat on the workpiece is significantly reduced.

2. Uniform heating: Heat is generated inside the object, unrelated to the shape and thermal conductivity of the object, which enables the entire thing to be heated to a uniform temperature, a feature that conduction heating does not have.

3. Selective heating: Different materials have different absorption rates of electric field energy. Selective heating at specific frequencies can improve heating efficiency and reduce energy consumption. For example, in the drying of wood panels and wood, selective heating can be applied. In addition, by controlling the electrode, it is possible to heat only the parts that need to be heated.

4. Controllability and applicability: It can be heated as soon as it is powered on and stopped when the power is off. Heating can also be controlled by time. Combined with electrical control, it can form efficient and automated equipment.

5. Working environment: No toxic, harmful gases or dust are produced during the production process, which is more in line with environmental protection requirements. By effectively controlling the high-frequency electric field radiation to meet national and international safety standards, it provides a suitable environment for operators.

Any integrated radio frequency heating equipment is equipped with a high-frequency vibration source. By configuring radio frequency generators with different power levels, different process requirements for workpiece heating can be met. High-frequency dielectric heating has the following main applications:

1. Plywood and MDF bonding: such as curved wooden chairs, sofas, bed frames, headboards, cabinet doors, engineered wood, raw wood blocks, guitars, pianos, and other musical instrument components.

2. Board splicing and bonding: integrated board splicing, furniture board, wooden strip edge sealing, door frame, L-shaped buckle line, wooden door assembly, cabinet door assembly, and furniture frame bonding.

3. Moisture explosion: wood drying, crops, food drying, textile industry moisture drying, and other substances that need to be dehydrated.

4. Special applications: fruit and vegetable insecticide, meat product decomposition, environmental protection industry, and printing industry, etc.

Our company's high-frequency generator has been tested by national authoritative departments and CE approval, and all indicators fully comply with the requirements of national environmental protection standards for high-frequency radiation. Users can use it with confidence!