What is edge glued panel?

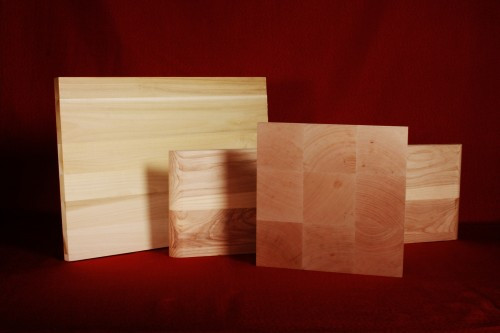

2023-12-29 16:07An edge glued panel, also known as a laminated panel or glued-up panel, is a type of wood panel made by joining individual wood boards or strips together along their edges. These boards are typically glued together using a strong adhesive, creating a larger, solid panel with a consistent thickness and width.

The edge glued panel offers several advantages:

Stability: By combining multiple smaller boards, the inherent movement and warping tendencies of solid wood are minimized. The resulting panel exhibits improved stability and reduced risk of distortion.

Enhanced Strength: The bonding between the boards increases the overall strength of the panel, making it more resistant to splitting, cracking, and impact.

Aesthetic Appeal: Edge glued panels often showcase the natural beauty of wood grains and patterns. They can be further enhanced through techniques like sanding, staining, or applying a finish to achieve a desired appearance.

Cost-Effectiveness: Edge glued panels allow for the utilization of smaller, narrower, or lower-grade wood boards that might otherwise be less desirable for other applications. This can result in cost savings compared to using larger or higher-grade solid wood panels.

It is also one of the environmentally friendly actions to save wood and protect the global environment.

What can make edge glued panels better?

A good machine!

Now, let's delve into the JYC full automatic high frequency wood board joining machine:

A full automatic high frequency wood board joining machine, also referred to as an automatic HF edge glued panel making machine, is an advanced woodworking machine designed specifically for joining wood boards using high frequency technology. This machine automates and streamlines the process of creating edge glued panels, providing increased productivity and consistency.

High Frequency Technology: The machine utilizes high frequency electromagnetic waves to generate heat, which activates the adhesive and facilitates rapid curing and bonding of the wood boards. This results in fast production cycles and strong, reliable bonds.

The Key features and benefits of course are Automation and Efficiency: The full automatic functionality eliminates the need for manual handling of each board, significantly reducing labor requirements and increasing production efficiency. The machine typically includes automated feeding, gluing, pressing, and discharging mechanisms, ensuring precise alignment and consistent panel quality.

Precision and Control: Automatic edge gluing machines offer precise control over variables such as pressure, temperature, and curing time. This allows for consistent and uniform bonding across the entire panel, minimizing defects and ensuring high quality results.

Versatility: These machines are capable of joining various wood species, sizes, and thicknesses, offering flexibility in panel production. They can accommodate different board widths and lengths, allowing for customization and meeting specific project requirements.

Quality and Durability: The automated process ensures accurate alignment and even pressure distribution during the bonding process, resulting in strong, durable panels with excellent structural integrity.

In summary, a full automatic HF wood board joining machine revolutionizes the process of creating edge glued panels. It combines the efficiency of automation with the speed and precision of high frequency technology, resulting in high quality, stable, and visually appealing wood panels suitable for a wide range of applications in the woodworking industry.

<br/>