Can You Dry Wood Without A Kiln?

2024-01-14 11:20Wood drying is a crucial step in woodworking and timber processing, as it ensures the stability and quality of the final product. Traditionally, kilns have been the go-to method for drying wood, but they can be expensive, time-consuming, and energy-intensive.

While kiln drying has been the industry standard, there are alternative methods available for drying wood. Air-drying, for example, involves stacking and exposing lumber to air circulation, allowing natural evaporation to remove moisture over an extended period. This method is suitable for certain applications, but it can be slow and weather-dependent, making it less ideal for commercial operations or projects with time constraints.

However, advancements in technology have given rise to high frequency vacuum wood dryer, offering a more efficient and cost-effective alternative to kiln drying. Let's explore the possibilities of drying wood without a kiln and discover the benefits of RF vacuum wood drying machines.

HF vacuum wood drying machines have revolutionized the wood drying process. These machines utilize advanced technology that combines high frequency heating and vacuum pressure to rapidly and efficiently remove moisture from wood. Unlike conventional kilns, high frequency vacuum timber dryer offer precise control over temperature, humidity, and pressure, resulting in faster and more consistent drying.

Benefits of High Frequency Vacuum Wood Drying Machines:

Speed and Efficiency: Radio frequency vacuum wood drying machines significantly reduce drying times compared to traditional methods. The combination of high frequency heating and vacuum pressure accelerates the evaporation of moisture from the wood, allowing for quicker turnaround and increased productivity.

Energy Efficiency: Radio frequency vacuum lumber drying machines consume less energy compared to kilns. By directly heating the wood and utilizing the vacuum to remove moisture, these machines optimize energy usage, resulting in cost savings and reduced environmental impact.

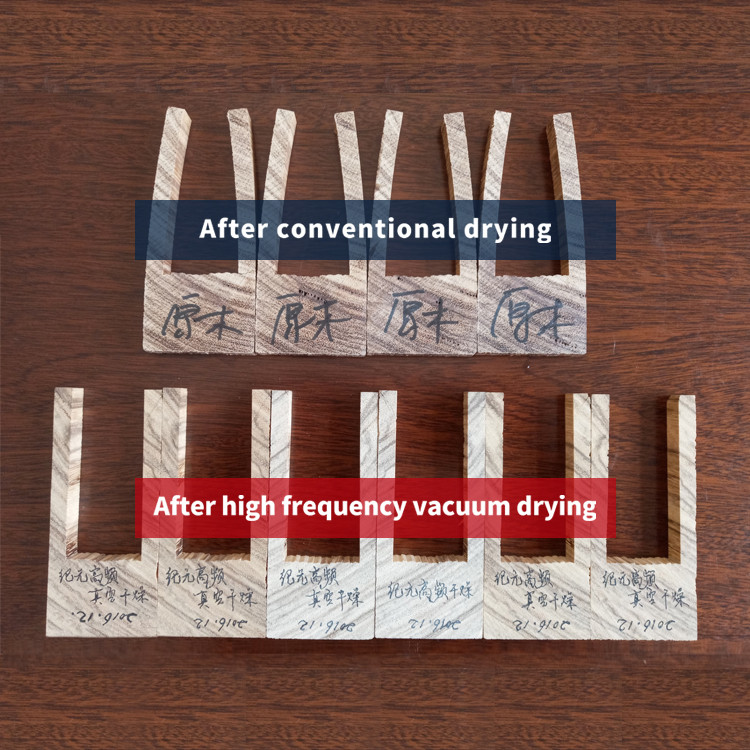

Improved Wood Quality: The controlled drying conditions offered by HF vacuum wood dryers contribute to higher-quality wood products. The rapid and uniform drying process minimizes the risk of defects such as warping, cracking, or mold growth, ensuring the wood retains its structural integrity and aesthetic appeal.

Versatility: RF vacuum wood dryers are suitable for a wide range of wood species and sizes, making them versatile for various applications. From furniture manufacturing to construction and woodworking industries, these machines can accommodate different project requirements and produce consistent results.

High frequency vacuum wood drying machines have emerged as a game-changer in the wood processing industry, offering an efficient and cost-effective alternative to traditional kiln drying. By eliminating the reliance on kilns, businesses can optimize their operations, enhance wood quality, and contribute to sustainability efforts. Just invest more to get higher quality and more efficient dry wood.