How Do You Process Wood Based Boards?

2024-02-03 15:35Secondary processing of wood based panels refers to the process of decorating the surface of wood based panels. The processed products are called secondary processed products of wood based panels or decorative wood based panels.

There are three main methods for the secondary processing of wood based panels:

1) Veneer method. Veneer materials mainly include decorative veneer (veneer), high-pressure melamine resin decorative laminated board (fireproof board), low-pressure melamine impregnated adhesive film paper, pre-painted paper, tissue paper, PVC film, cork, metal foil, textiles, etc.

The veneer can use our high frequency wood laminating machine. JYC HF wood laminating machine can use high frequency heat, and fast cure the glue between wood and wood. Radio frequency wood laminating machine can so easy and efficiently veneer on the solid wood door or laminating melamine veneer on wood board, etc. (Notice: our machine cannot work for other materials, just work on wood.)

2) Painting method. There are coating, direct printing, transfer printing, etc.

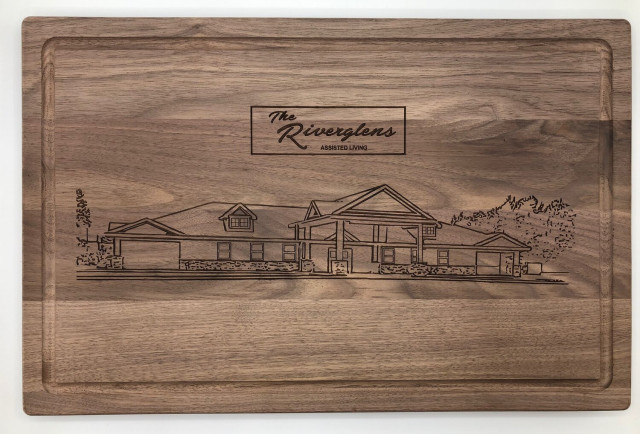

3) Mechanical processing method. There are molding, milling, laser engraving, hand engraving, drilling, slotting, scraping, etc.

The above three processing methods can be used alone or at the same time. Usually, wood based panels need to be processed twice before being processed into various downstream products, such as furniture, floors, wooden doors, etc. Some wood based panels are directly processed into products before being subjected to secondary processing such as painting. After secondary processing of the wood based board, the surface decoration can be improved; it can prevent moisture from penetrating into the board and causing deformation, and prevent aging caused by ultraviolet rays; it can make the surface have physical and chemical properties such as wear resistance, heat resistance, iron resistance, scratch resistance, and pollution resistance; prevent Formaldehyde and other harmful gases are released in the board. In this way, the wood based panels can meet various usage requirements, improve the usage value, expand the scope of usage, and bring better economic benefits to the production enterprises.