How to dry wood without cracking?

2023-09-08 16:26As you know, raw wood cannot be made into furniture directly, it has a lot of moisture not good for making into furniture. Too much moisture in wood, made into furniture, it will become not durable furniture, and easily get moldy or crack because of temperature changes.

Here are some tips for making the wood no deformation, no discoloration, and no cracks:

Proper moisture content measurement: Accurate measurement of the initial moisture content of the wood before drying is essential. This helps determine the optimal drying parameters and prevents over-drying or under-drying.

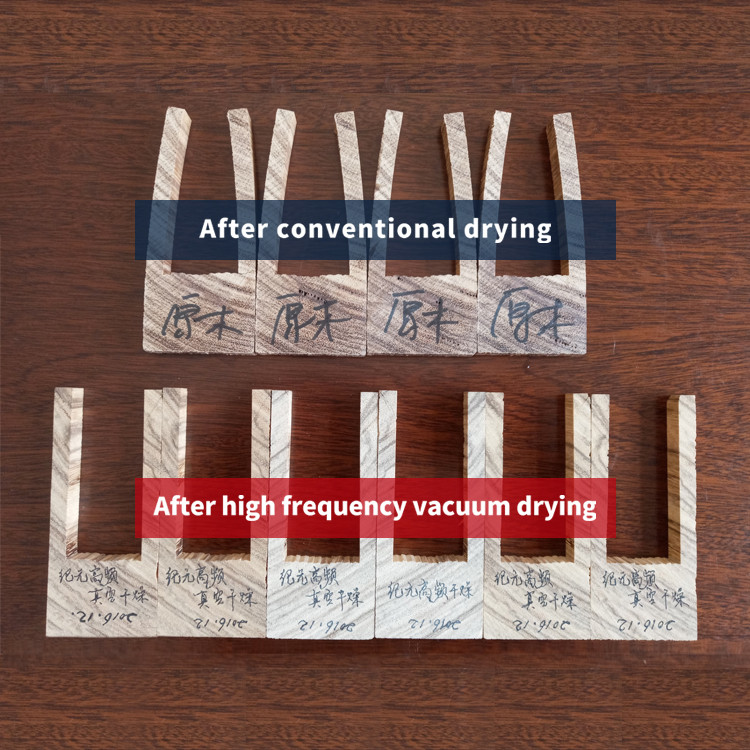

The wood drying before & after using JYC High Frequency Wood Vacuum Drying Machine

Controlled drying conditions: Maintaining consistent and controlled drying conditions, including temperature, humidity, and airflow, is crucial. This helps ensure uniform drying and minimizes the risk of discoloration and cracking. Monitoring and adjusting these conditions throughout the drying process can further optimize the results.

Gradual moisture removal: Implementing a gradual drying process allows for the gradual release of moisture from the wood. Rapid drying can lead to uneven moisture distribution and increase the likelihood of defects such as cracking. Controlling the drying rate helps maintain wood integrity.

The wood is cracking after drying with no right wood drying equipment

Proper stacking and airflow: Arranging the wood properly in the drying area promotes efficient airflow. This allows for even circulation of air around the wood, facilitating moisture evaporation and reducing the risk of mold growth or uneven drying.

Conditioning and rest period: After the initial drying phase, allowing the wood to rest and reach moisture equilibrium is important. Conditioning the wood helps equalize the moisture content throughout the wood, reducing the potential for post-drying defects like warping or cracking.

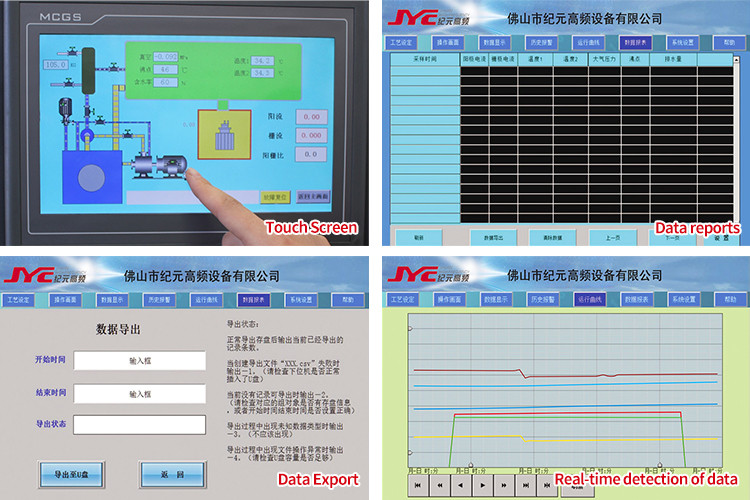

Quality control and monitoring: Regular inspection of the wood during the drying process is essential to identify any issues promptly. This allows for necessary adjustments to the drying conditions, ensuring the desired drying quality.

By implementing these measures, it is possible to achieve efficient wood drying while ensuring that the wood dries quickly without discoloration and cracking.

JYC High frequency wood vacuum drying machine equipped with multiple temperature sensing and monitoring device can let the wood drying in a stable process. JYC HF lumber dryer delivers high frequency heating, which heats the wood inside and outside at the same time. It won't crack while the wood is drying.

Lots of customers trust JYC, and choose JYC's machine. JYC Radio frequency vacuum timber drying machine can let the wood achieve the moisture content measurement that it requires. Also, the quality of the wood is marvelous!