How to make curved panels?

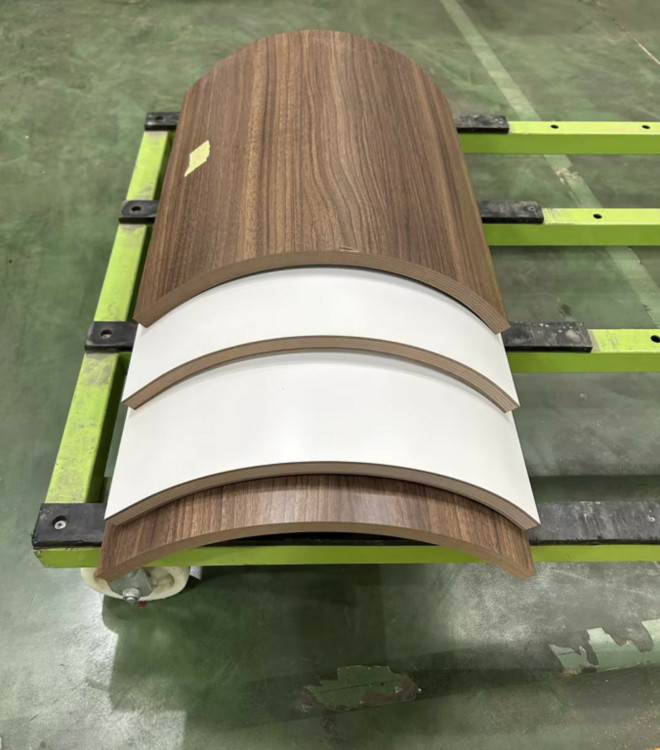

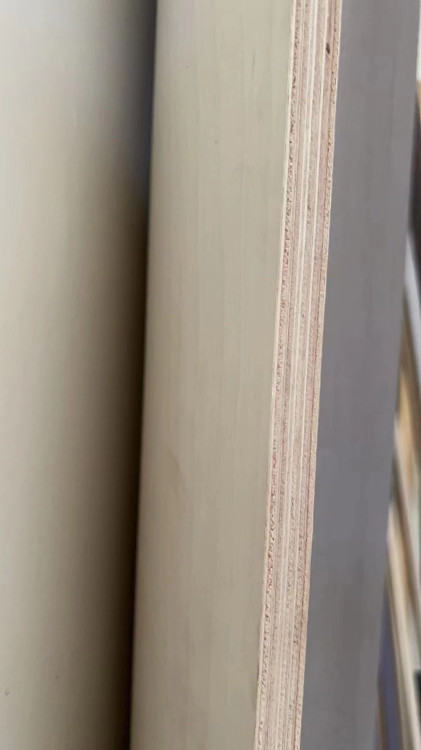

2023-07-11 15:18Curved panels can be classified into two types: unpainted and wood veneer painted. The former is commonly used for whole house customization and is made of medium-density fiberboard, while the latter is used for high-end customization and is made of plywood.

Arc-shaped wall panels and arc-shaped door panels are very popular. Do you know what manufacturing process is used to create them?

Arc-shaped wall panels and arc-shaped door panels have become one of the hottest trends in the current "integrated door-wall-cabinet" wave due to their smooth curved artistic beauty, better space utilization, and novel and stylish design.

01

How to make curved panels by traditional woodworking techniques for bending wood?

Traditional bending wood techniques typically fall into three categories:

1. Steam bending wood

2. Laminating wood

3. Kerf bending wood

Traditional woodworking techniques for bending wood to make arc-shaped panels have some drawbacks that affect their efficiency:

1. Bending a single board can take 5-6 hours, which is relatively slow.

2.These techniques require a lot of manual labor, which can be physically demanding. Traditional techniques rely on the expertise of highly skilled craftsmen, making it difficult to achieve fast mass production and leading to high labor costs.

3. The process is mainly done by hand, making it challenging to achieve large-scale production.

4. Panels over 2.4 meters in length may need to be spliced, which can result in misalignment.

5. Additionally, the wood is prone to cracks, rebound, and deformation.

02

How about the efficiency of using high frequency bending wood press?

The efficiency of using a high-frequency bending wood press machine for making arc-shaped panels is significantly higher than traditional woodworking techniques.

High-frequency bending plywood press machine is currently one of the most intelligent and advanced techniques for bending plywood to make curved panels. The machine has gained recognition and popularity among custom factories due to its numerous advantages:

1. High efficiency: The process is much faster than traditional techniques, allowing for more rapid production. It only takes 5-6 minutes to produce one arc-shaped panel using the machine, while traditional techniques require 5-6 hours to shape a panel.

2. Low labor intensity: The process requires only 1-2 people and involves low labor intensity, reducing the risk of work-related injuries.

3. Fast mass production: The high-frequency bending wood press machine can quickly achieve fast mass production, which is difficult to realize with traditional techniques.

4. Stability: The one-piece forming process ensures the stability of the finished product, eliminating the need for splicing and reducing the risk of misalignment.

5. After-sales issues: The finished product is stable, with no cracking, rebound, or deformation.

6. Low labor cost: Using high-frequency bending wood press machines reduces labor costs, making it a cost-effective solution.

7. High precision: The high-frequency heating and shaping process ensures high precision and reduces the risk of deviation, rebound, and deformation, which are common issues with traditional cold pressing techniques due to human errors.

03

What are the requirements for the applicability of the board made of curved boards by high-frequency bending wood technology?

Curved panels can also be divided into two types: unpainted and wood veneer painted. The former is used for full-house customization, and the substrate is mostly medium density fiberboard (MDF); the latter is used for high-end customization, and the substrate is mostly plywood.

We can analyze the differences between wood veneer substrate and MDF substrate in terms of bending thickness, bendable radius, substrate moisture content, and maximum height:

1. Bending thickness:

The wood veneer surface layer thickness should be between 1-3mm, while the MDF substrate surface layer thickness should be between 2-5mm.

2. Bendable radius:

The wood veneer surface layer can be bent with a radius of 40mm or greater, while the MDF substrate surface layer can be bent with a radius of 100mm or greater.

3. Moisture content requirements:

The moisture content requirement for wood veneer is 6-8%, while MDF substrate can be produced with a wide range of moisture content.

4. Maximum height:

Both wood veneer and MDF substrate do not have any height restrictions, and can be molded into any height without the need for splicing.

How do these custom furniture companies make curved panels?

Currently, many custom furniture factories and some decorative panel factories use the JYC high-frequency bending wood technology to produce curved panels. Some of these factories have purchased more than ten JYC HF bending wood machines to meet the high demand in the market.

By using the JYC radio-frequency bending wood machine to produce arc-shaped panels, these factories have greatly saved on labor costs. The bending time for one curved panels only takes 5-6 minutes, which is more than 60 times faster than traditional methods, greatly improving production efficiency.