What is the best way to bend plywood?Make the plywood bending easily

2023-04-22 15:121. Curved Panels Are Widely Used In Advanced Customization Home Furnishing

People who pursue a perfect home, have more ideas for their home renovation. But interior renovation generally has these problems: low space utilization rate, single function, small apartment size, bad appearance, inconsistent style, etc.

In recent years, "integration of doors, walls, and cabinets", "Sofa or desk or even multifunctional bed, size customization", and "curved panel for the wall corner", and "curved panel for the cabinet corner", etc have also been frequently mentioned in the demand for whole house customization.

The wide application of curved plate in the customization of the whole house, and even the consistency of "door, wall and cabinet", is due to its practicability, which reflects the novel and elegant taste in the large apartment, the practical and beautiful appearance in the medium apartment, and the better use of space in the small apartment.

2. About Curved Household Products

The so-called "curved wood", as the name implies, is to bend the wood, not only to create smooth and beautiful but also to maintain the integrity and durability of the wood texture. Curved wood furniture, triggering a new trend of furniture modeling, which is a modernist work, represents people's new aesthetic pursuits and experiences.

The modern curved wood process originated in Northern Europe and had an extraordinary impact as soon as it appeared. So far, it has created many world-famous home products and is considered a revolutionary leap in the production of wood furniture.

The bending usually consists of solid wood strip bending and multilayer veneer bending, which are very different. The bending process of solid wood is very demanding, and the selection of materials is very strict. It needs to be cooked or softened at high temperatures and then dried.

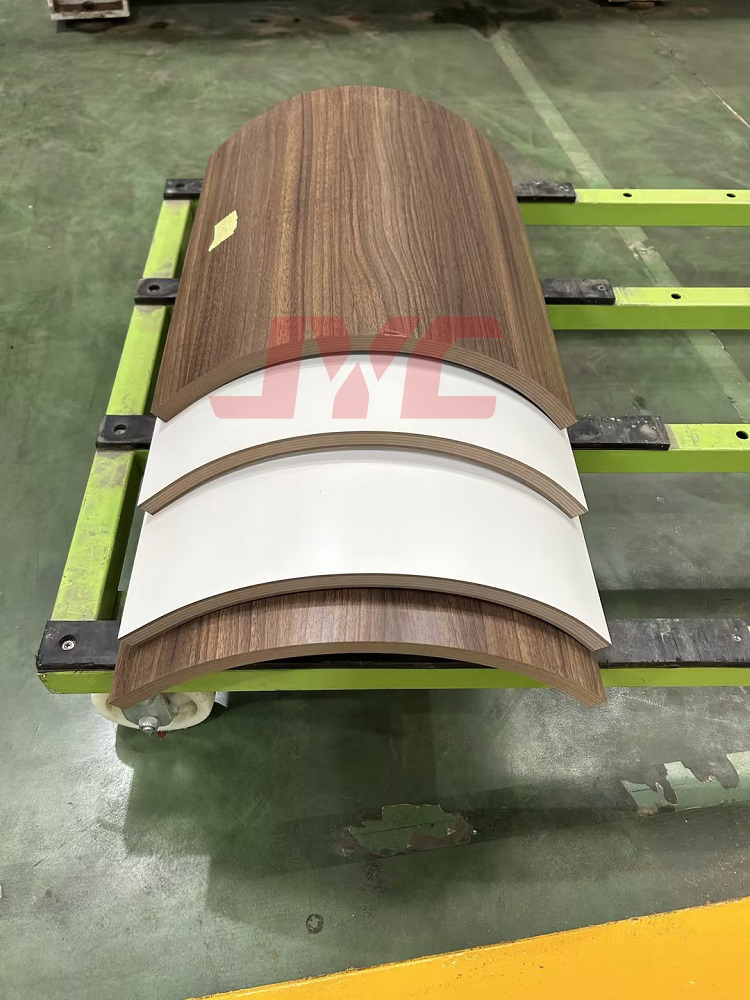

Wood gluing and bending is a perfect combination of technology and art. Wood bending process is the wood veneer (rotary veneer) or wood strip, laminated placement and heating, it will be processed into household products needed to bend parts.

The furniture produced by the multi-layer adhesive bending process can be bent on a large curved surface according to the use requirements. It has the advantages of moisture resistance, torsion, cracking, and deformation. Its beautiful arc is unmatched by other furniture.

Curved wooden furniture has a unique shape, beautiful appearance, simple and elegant appearance, and strong design sense. In the production of modern furniture, different shapes and different sizes of curved pieces are the keys to manufacturing.

3. The Integrated Forming Process of Curved Panel

3.1 The benefits of curved panels integrated molding

Curved panels and curved cabinet doors, as a new application of old technology in the integration of "doors, walls, and cabinets", inevitably have some process or after-sales problems, such as low production efficiency, easy rebound, etc. The JYC bentwood press machine adopt the "integrated molding" method, compare with traditional curved panels method that need to jigsaw puzzle, which has more advantages in terms of aesthetics and stability, there are three reasons:

3.1.1 curved panels integrated molding can achieve relatively balanced internal stress of the panels and is not easy to rebound

3.1.2 Integrated molding reduces the steps of jigsaw puzzle, which also avoid the deformation of the jigsawing gap due to external factors such as temperature and humidity changes in the use scene (especially the height exceeds 2.44 meters for the standard panels, the traditional method which is cold pressing basically need to jigsaw the curved panels, for example, when it is necessary to process a curved panel as high as one floor, like 3meters height);

3.1.3 Integrated molding, no need for jigsawing, and there will be no misalignment of the jigsawing of the curved panel itself, which will affect the aesthetics of the integration, and it is also not easy to have after-sales problems such as misalignment of jigsawing parts and deform in the use scene due to long-term force or moisture.

3.2 The equipment for integrated curved panel one-step forming

The production of curved panels have pretty different from other household parts and requires more processes, especially for curved door panels and curved wall panels that meet a particular height requirement. If you used the traditional cold pressing method, not only is it takes more time and labors, but also triggers to after-sales problems such as significant arc errors and rebound. If you want to achieve high-quality mass production, the mainstream is still hot pressing technology such as high-frequency bending wood pressing.

3.2.1 A long history of high-frequency hot-press bending technology

The high-frequency hot pressing technology application among global woodworking machinery companies can be traced back to 1993, even earlier. At the beginning of the establishment of Jiyuan High-frequency Woodworking Machine Enterprise(JYC), it took the lead in applying high-frequency technology to the bending and shaping of solid wood and laminated boards(Plywood or multi-veneers). It has been more than 30 years. JYC has quite rich experience in using high-frequency hot pressing technology.

3.2.2 High efficiency in the procession

The way of high-frequency hot pressing can promote the penetration of glue more quickly and effectively, and increase production efficiency. Moreover, the curved panel by the traditional cold-pressed method needs 5-6 hours of waiting for the glue to dry and shape, while the high-frequency hot-pressing only takes a few minutes for penetration and solidification of glue.

3.2.3 one-step Integrated molding curved panel is more stable and does not rebound

Even curved wall panels with a height of more than 2.44 meters can be integrally pressed and formed by a high-frequency wood bending machine, eliminating the need for jigsawing for the height, decreasing the possibility of misaligned jigsawing between panels, and reducing the internal tension of wood and the problems of moisture and deformation caused by many jigsawing pieces.

4. Epilogue

Rich technical experience is the guarantee of product quality, and product stability is the foundation of a good brand and good reputation.

For furniture factories, panel factories, and interior renovation companies, curved panels are currently a breakthrough point that is very beneficial for factories to use as brand promotion points and product differentiation.