JYC solid wood panel automatic line helps the technology upgrade of world-class home furnishing brands supplier

2023-05-11 14:51In Dongguan, China, there is a world-class home furnishing brand manufacturer covering an area of more than 10,000 square meters. It is engaged in solid wood paneling, solid wood painting, furniture manufacturing, etc., and its production capacity, equipment, and technology are at the leading level in the industry.

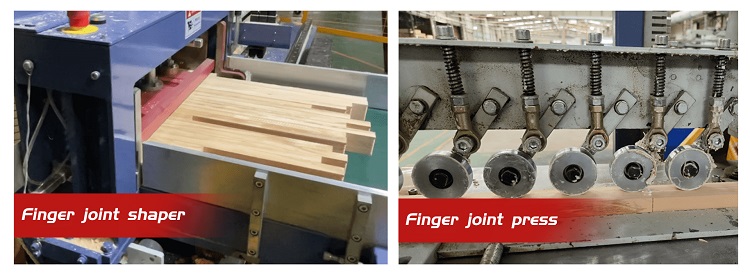

After choosing the JYC high-frequency automatic wood panel joining production line, the manufacturer opened a new stage of automatic production of finger-joined pine panels: the pine wool is cut by multi-blade saws, and the screened wood and milling machines are used for finger-joining, and sawtooth and short board finger jointing to longboards, and to four-sided planing, high-frequency board side joining machine, and palletizing, To sum up, JYC assisted them in realizing full automation of the entire process from logs to joining into large planks.

1. Why do world-class furniture manufacturers choose JYC

As a woodworking equipment supplier selected by this manufacturer many times in a row - JYC stands out among similar enterprises with its high-quality service and professional technology and wins their favor.

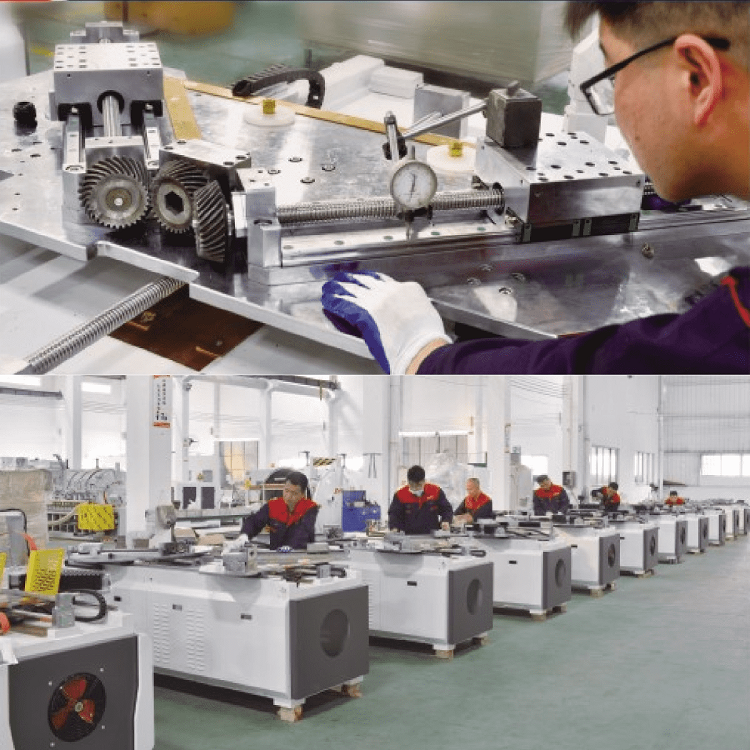

JYC is not only a company that has been focusing on the manufacture of high-frequency woodworking machinery for more than 30 years. JYC not only provides professional and stable equipment but also knows the importance of after-sales technical services. JYC's after-sales service is high-quality and considerate.JYC's professional and technical personnel are on call at any time and respond to online consultations at any time. More importantly, JYC's after-sales technicians have received professional training and have no less than 10 years of equipment service experience. Combined with the accumulation of JYC's technical archives for more than 30 years, they can always quickly understand customers' problems and needs, problems encountered in production (whether it is the machine itself or wood, glue, etc.), and patiently communicate with customers to solve problems efficiently.

▲JYC technicians

2. JYC high-frequency automatic joining panel production line technology upgrade

JYC's high-frequency automatic panel production line inherits the advantages of traditional high-frequency panel machines such as "high flatness", "high efficiency", and "wide applicability", and has made a big step forward in "cost reduction and efficiency increase".

2.1 Intelligence: It is equipped with a self-developed intelligent operating system, which realizes automatic operations from the entire paneling process such as "feeding, glue mixing, glue coating, board arrangement, high-frequency pressing, and palletizing".

The operator only needs to input the corresponding processing parameters on the touch control screen according to the actual production demand, and then "one-button control" the entire production line, which reduces labor costs by 70% and reduces labor intensity.

2.2 Further cost-reduction: JYC's high-frequency automatic paneling line can save more than 25% of the amount of gluing on the board compared with manual gluing, and the amount of sanding reserved for each panel can be reduced by 0.25mm compared with conventional paneling. Calculated by producing 500 standard boards per day (take the standard board of 1220*2440mm as an example), 12-13 cubic meters of wood can be saved in one month.

2.3 Re-increasing efficiency: It only takes 1-2 minutes from loading to board output, compared with 4-5 hours to assemble a board in the traditional way, and the production efficiency of the high-frequency automatic board-making line has increased by more than 100 times.

2.4 More labor-saving: fully automatic board joining operation, only needs one person to operate, low labor intensity, greatly improving production efficiency. In addition, this production line can also be directly connected to other production lines, such as four-sided planning, to realize the "automatic feeding" function.

2.5 Higher stability: Nano-coated chain plate conveyor belt is used, glue-free cleaning, eliminating the labor of manual cleaning of the conveyor belt. At the same time, the most important thing is to avoid the influence of the traditional board joining machine on the flatness of the conveyor belt due to the need to repeatedly clean the glue. JYC's nano-scale coated chain conveyor belt has higher stability and durability.

2.6 Unequal width: Intelligently complete the paneling operation for materials of equal or unequal width. The panel production line can intelligently adjust high-frequency power, pressure, pressurization time, and pressure holding time according to wood material, glue characteristics, length and width, etc. Regardless of equal width or unequal width, or even a slight width deviation, JYC high-frequency wood joining machine can edge joint high-quality wood perfectly and quickly.