The Environmental Impact of High Frequency Wood Drying Machines

2024-02-12 10:20In recent years, there has been growing concern about the environmental impact of industrial processes. In this article, we will explore the environmental aspects of high frequency vacuum wood drying machines and discuss their potential benefits in reducing the environmental footprint in the woodworking industry.

Energy Efficiency and Carbon Footprint:

HF wood drying machines are known for their energy efficiency, which directly contributes to reducing carbon emissions. These machines utilize targeted heating to dry wood, minimizing energy waste. By consuming less energy, manufacturers can significantly reduce their carbon footprint and contribute to a more sustainable production process.

Reduced Chemical Usage:

Unlike conventional drying methods that often require the use of chemicals to prevent mold, fungus, and insect infestation, radio frequency vacuum wood drying machines offer a chemical-free drying process. The controlled heat generated by these machines effectively eliminates the need for chemical treatments, reducing the release of potentially harmful substances into the environment.

Waste Reduction:

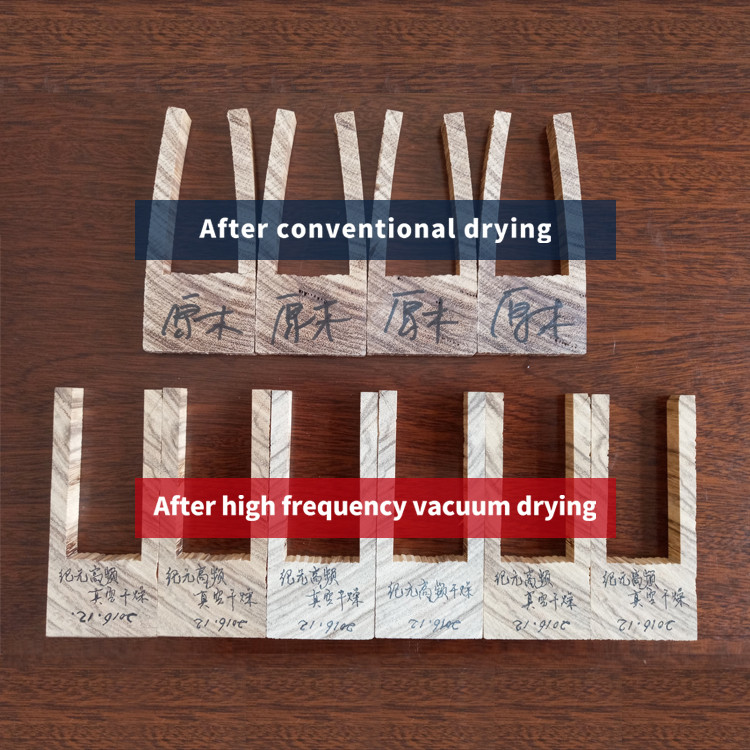

High frequency vacuum wood drying machines contribute to waste reduction in the woodworking industry. The faster drying times and improved wood quality achieved through these machines result in reduced material waste. Additionally, the precise control over the drying process minimizes the risk of defects, further reducing waste and improving overall resource efficiency.

Sustainable Wood Sourcing:

The use of HF timber drying machines can encourage sustainable wood sourcing practices. With faster drying times, manufacturers can process wood more efficiently, reducing the demand for freshly cut timber. This, in turn, can promote the use of reclaimed or sustainably harvested wood, supporting responsible forestry practices and biodiversity conservation.

Potential for Renewable Energy Integration:

HF vacuum wood dryers have the potential to integrate renewable energy sources into the drying process. As renewable energy technologies continue to advance, manufacturers can power these machines with clean energy, further reducing their environmental impact and dependence on fossil fuels.

Conclusion:

High frequency vacuum wood drying machines offer several environmental benefits, including energy efficiency, reduced chemical usage, waste reduction, and the potential for renewable energy integration. By adopting these machines, manufacturers can contribute to a more sustainable woodworking industry, reducing carbon emissions, minimizing chemical waste, and promoting responsible wood sourcing practices. As environmental concerns continue to grow, HF vacuum wood drying machines present an opportunity to align industrial processes with sustainability goals.