What Makes The Timber Cracking and Discoloration?

2024-07-10 16:29Wood drying is a critical process in woodworking, influencing its quality and durability. The other traditional methods often fall short of preventing defects like cracking and discoloration. However, high frequency vacuum wood drying machine has emerged as a superior alternative, offering distinct advantages in preserving wood integrity. This article contrasts conventional drying methods with HF vacuum wood drying machine, highlighting its effectiveness in maintaining wood quality.

Conventional Drying Challenges

Conventional drying methods, such as air drying and kiln drying, face inherent challenges that impact wood quality. Air drying, while cost-effective, is slow and inconsistent, leading to uneven moisture levels and increased susceptibility to cracking.

Kiln drying, on the other hand, accelerates the process but can cause significant stresses within the wood fibers, resulting in warping, checking, and undesirable color changes. These issues often compromise the structural integrity and aesthetic appeal of the wood, limiting its applications.

High Frequency Vacuum Drying: A Breakthrough Technology

High frequency vacuum drying represents a breakthrough in wood drying technology, addressing the shortcomings of traditional methods. This process involves subjecting wood to electromagnetic waves at high frequencies, combined with a vacuum environment. The synergistic effect of these elements accelerates moisture extraction while minimizing detrimental effects on the wood.

Advantages of High Frequency Vacuum Drying

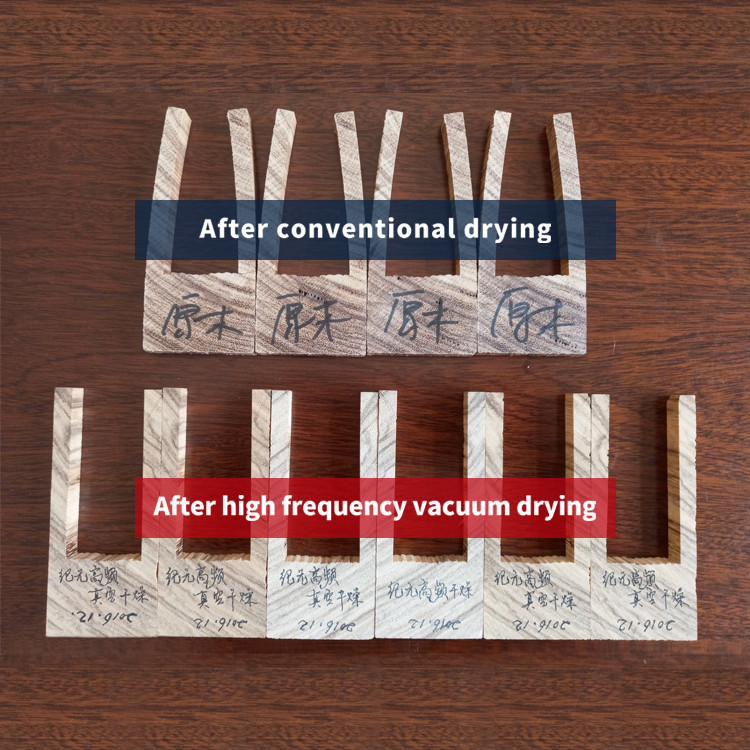

Reduced Cracking: One of the most significant advantages of radio frequency vacuum wood drying machine is its ability to minimize cracking in wood. By quickly and evenly removing moisture from within the wood fibers, this method reduces internal stresses that cause cracking during drying. The vacuum environment prevents the formation of steam pockets, which are a common cause of surface and internal cracks in traditional drying methods.

Preserved Color and Texture: Wood dried using high frequency vacuum technology retains its natural color and texture. Unlike kiln drying, which often results in darkening or uneven coloring due to high temperatures and prolonged exposure, radio frequency vacuum wood dryer operates at lower temperatures and shorter cycles. This gentle approach preserves the wood's original appearance, making it suitable for high-end applications where aesthetics are crucial.

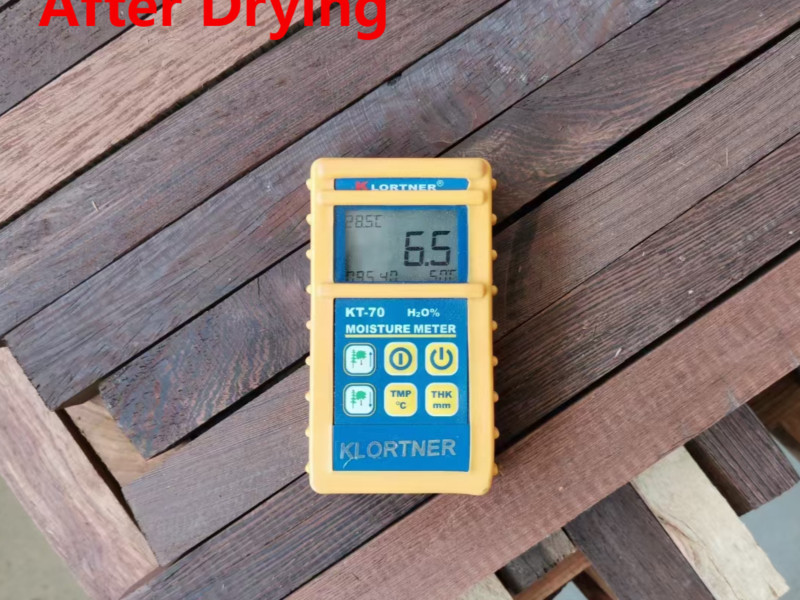

Uniform Moisture Content: Consistency in moisture content is vital for the dimensional stability of wood. High frequency vacuum wood drying kiln ensures uniform moisture removal throughout the wood, reducing the risk of warping and distortion. This precision is particularly advantageous for manufacturing furniture, musical instruments, and flooring, where dimensional stability is non-negotiable.

Energy Efficiency: While traditional kiln drying consumes significant energy, high frequency vacuum wood drying machine is more energy-efficient. The shorter drying cycles and lower operating temperatures contribute to reduced energy consumption, making it both environmentally friendly and cost-effective in the long term.

Conclusion

In conclusion, HF vacuum wood dryer stands out as a superior method for drying wood, particularly in industries that demand high quality and precision. By minimizing cracking, preserving natural color and texture, ensuring uniform moisture content, and enhancing energy efficiency, this technology sets a new standard in wood drying. As demands for sustainable and high-performance materials grow, the advantages of high frequency vacuum timber drying machine are increasingly recognized, offering a promising future for woodworking industries worldwide.