What's Different Between High Frequency Single Direction Wood Bending Press and High Frequency Three Direction Wood Bending Press?

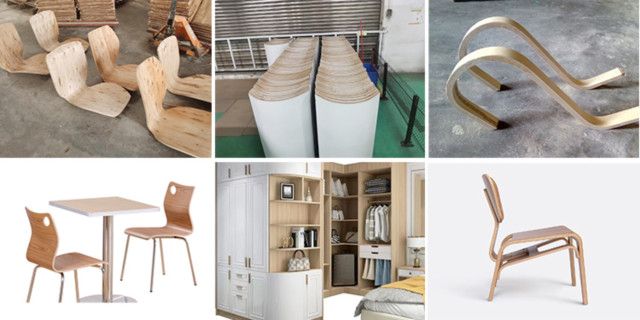

2024-01-27 15:32In woodworking, the ability to bend wood to achieve desired shapes and forms is a valuable skill. High frequency wood bending presses have revolutionized this process by applying radio frequency electromagnetic waves to heat and cure the glue. In this article, we will explore the key differences between two popular types of high frequency wood bending presses: the single direction wood bending press and the three direction wood bending press. Analyzing their unique characteristics will help professional woodworkers and furniture manufacturers understand the advantages and applications of each.

High Frequency Single Direction Wood Bending Press:

The HF single direction wood bending press is designed to bend wood along a single axis. Here are some notable features:

a. Flexibility in Bending Length: Single direction presses are suitable for bending longer pieces of wood, such as boards or planks. This makes them ideal for creating curved components in furniture making or architectural applications.

b. Simplified Operation: Single direction presses typically have straightforward controls and mechanisms, making them easier to operate and maintain. They are often preferred by woodworkers who require simplicity and efficiency in their bending processes.

c. Efficient Heat Transfer: The single direction design allows for focused heating on the area being bent, ensuring efficient heat transfer and consistent bending results. This targeted heating minimizes the risk of overheating or underheating, leading to more precise and reliable bends.

Radio Frequency Three Direction Wood Bending Press:

The RF three direction wood bending press offers additional capabilities and versatility compared to the single direction press. Here are its distinguishing features:

a. Multi-Axis Bending: Three direction presses can bend wood along three axes, enabling complex curved shapes and intricate designs. This versatility makes them suitable for creating more elaborate woodworking projects, such as curved staircases, musical instrument components, or artistic sculptural pieces.

b. Enhanced Control and Precision: The ability to bend wood along multiple axes requires more advanced control systems. Three direction presses often offer greater adjustability in terms of temperature, pressure, and bending angles. This precision allows woodworkers to achieve highly customized and intricate bends with consistent results.

c. Increased Production Capacity: With the ability to bend wood in multiple directions simultaneously, three direction presses can significantly enhance production efficiency.

Both HF single direction wood bending presses and HF three direction wood bending machines offer unique advantages depending on the specific requirements of a woodworking project. Single direction bending wood machines excel in bending longer pieces of wood with simplicity and efficiency. In contrast, three direction presses provide greater versatility, precision, and production capacity for more complex and intricate designs. Three direction presses can press the shape of a single direction wood bending machine, but a single direction press cannot press the intricate curve shape. So considering the customer's sufficient budget, we recommend that the customer purchase a three direction bending wood press. That is more useful.

HF single direction wood bending presses