Why More And More Wood Board Manufacturers Use HF Wood Board Joining Machine?

2024-02-28 16:22In the ever-evolving landscape of woodworking technology, innovations continue to push the boundaries of efficiency and quality. In this article, we delve into the intricacies of these machines, exploring their features, benefits, and the transformative impact they bring to woodworking industries worldwide.

Understanding High Frequency Edge Glued Board Joining Machines:

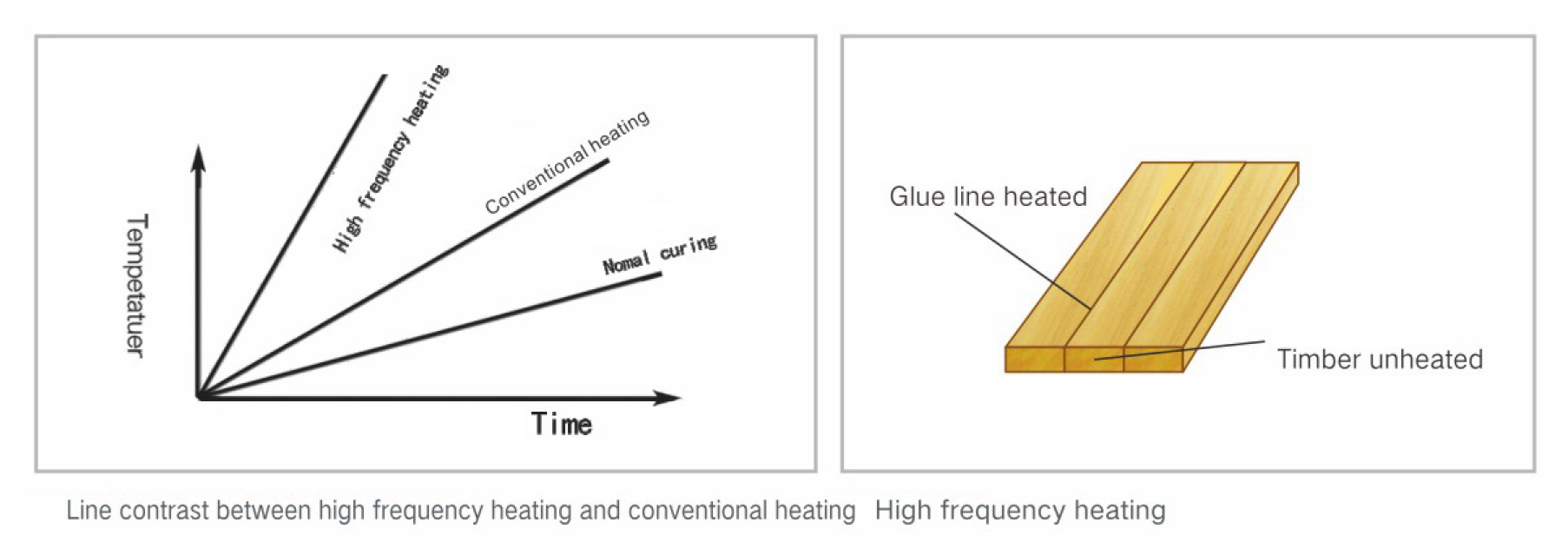

HF edge glued board joining machines are sophisticated pieces of equipment designed to streamline the process of joining wooden boards. Unlike traditional methods such as gluing and clamping, these machines utilize high frequency electrical currents to create strong and durable bonds between wood pieces. The process involves applying adhesive to the edges of the boards, placing them together, and subjecting them to high-frequency waves, which cause the molecules in the adhesive to vibrate and create a powerful bond.

Key Features and Components:

High Frequency Generator(it on the top of the HF edge glued board joining machine): At the heart of these machines lies the HF generator, which produces the electrical currents necessary for the joining process. This generator is equipped with advanced technology to ensure precise control over frequency and intensity, resulting in consistent and reliable bonding.

Press System: The press system applies pressure to the boards during the joining process, ensuring uniform contact between the adhesive and wood surfaces. It is designed to exert the optimal amount of pressure without causing damage to the wood, thereby maximizing bond strength and minimizing waste.

Conveyor System: A conveyor system facilitates the movement of boards through the joining machine, allowing for seamless integration into existing production lines. This feature enhances workflow efficiency and productivity, enabling woodworkers to meet high demand without sacrificing quality.

Heating Elements: Heating elements are strategically positioned within the machine to regulate temperature during the bonding process. Maintaining the ideal temperature is crucial for ensuring proper adhesive curing and achieving strong, durable bonds.

Benefits of Radio Frequency Edge Glued Board Joining Machines:

Superior Bond Strength: One of the primary advantages of high frequency edge glued board joining machines is the exceptional bond strength they provide. The high frequency waves penetrate deep into the wood and adhesive, creating bonds that are stronger and more durable than those achieved through traditional methods.

Increased Productivity: By automating the joining process and minimizing the need for manual intervention, these machines significantly increase productivity. Woodworkers can produce a higher volume of edge glued boards in less time, allowing them to meet tight deadlines and customer demands more effectively.

Enhanced Quality Control: Consistency is key in woodworking, and RF edge glued board joining machines excel in delivering uniform results. With precise control over factors such as pressure, temperature, and adhesive application, these machines minimize variations and defects, ensuring consistently high-quality finished products.

Versatility: High frequency edge glued board joining machines are highly versatile and can accommodate a wide range of wood species, sizes, and shapes. Whether working with hardwoods, softwoods, or engineered wood products, woodworkers can rely on these machines to deliver superior bonding performance across various applications.

Cost Savings: While HF edge glued board joining machines represent a significant investment upfront, they offer long-term cost savings through improved efficiency and reduced waste. By optimizing material usage and minimizing rework, woodworkers can lower production costs and enhance profitability over time.

High frequency edge glued board joining machines find applications across diverse woodworking industries, including furniture manufacturing, cabinetry, millwork, and architectural woodworking. From producing tabletops and panels to constructing doors and frames, these machines play a vital role in creating high-quality wood products with superior strength and durability.