- Home

- >

News

This article explores the applications of HF wood board joining machines and highlights JYC’s competitive advantages through data-driven comparisons.

It’s a technology that produces consistently stronger, more reliable joints, ultimately leading to more durable and longer-lasting wood creations.

The demand for high-quality, thin wood panels is ever-increasing across diverse industries, from furniture manufacturing and interior design to construction and crafts.

It’s time to step into the future of woodworking efficiency and precision with the self-weight bottom glue spreader – the perfect partner for your high frequency wood board joining machine.

Wood panel manufacturers may all have this question: Can All Wood Panel Manufacturing Use High Frequency Wood Board Joining Machines? Not Quite.

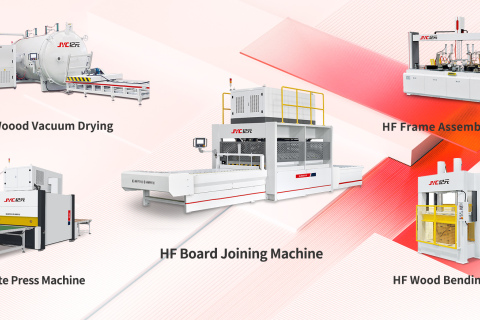

In the fast-paced world of woodworking, efficiency, precision, and durability are paramount. And perhaps you don't know that JYC have different wood board joining machines for different requirements.

We cordially invite you to visit our booth to explore our latest machinery and innovations.

When joining two pieces of wood, achieving a straight, seamless bond is essential for both aesthetic and structural integrity.

Solid wood material preparation is an extremely important front-end task in home furnishing manufacturing production.

In furniture manufacturing, the front-end solid wood preparation primarily encompasses key processes such as drying, cutting (finger jointing), and panel assembly, directly impacting raw material utilization, subsequent processing efficiency, and the final product quality. However, amidst the current trend of automation upgrades, solid wood preparation still faces numerous challenges in efficiency and quality.