Drying technology that can keep solid wood furniture from cracking and swelling

2023-04-26 16:48Wood is one of the earliest raw materials developed and utilized by human beings. It has been integrated into all aspects of the living environment such as home and office, and the most widely used one is in the field of furniture. Today, with highly developed industrialization, countless wooden pieces of furniture travel all over the world and enter thousands of households every year, and the after-sales problem of solid wood furniture also plagues many home furnishing companies.

Especially in the rainy season, solid wood furniture is prone to cracks, swelling, and deformation caused by moisture, especially for some enterprises with a wide geographical range of business, such as manufacturers in areas with relatively low geographical latitudes. When exported to regions with relatively high geographical latitudes, such solid wood furniture is prone to wood cracking, or conversely, when transported from high latitude areas to low latitude areas, it is prone to moisture expansion and deformation of the wood. These are often related to whether the wood has been scientifically dried before being made into furniture.

1. Gain Insight Into The Moisture Content of Wood

We all know that the drying of wood is closely related to the moisture content of wood, and the moisture content of wood without special treatment often varies greatly, so most of the wood needs to be dried in layers in a targeted manner, that is, to balance its moisture content, so as to ensure the quality of the board and increase its stability after long-term storage and even processing into finished furniture.

Let's first understand the impact of the moisture content of wood on drying:

1.Different wood has a different moisture content

The moisture content of different wood species is different, and even the same species of wood will have great differences in moisture content.

2. The natural movement and change of moisture in wood

After felling the wood, in an unstable external environment or during the drying process, the internal components of the wood will undergo physical and chemical changes, resulting in corresponding changes in the structure of the wood. How to balance and reduce the moisture content in the wood faster and better is an inevitable important problem in the wood drying process.

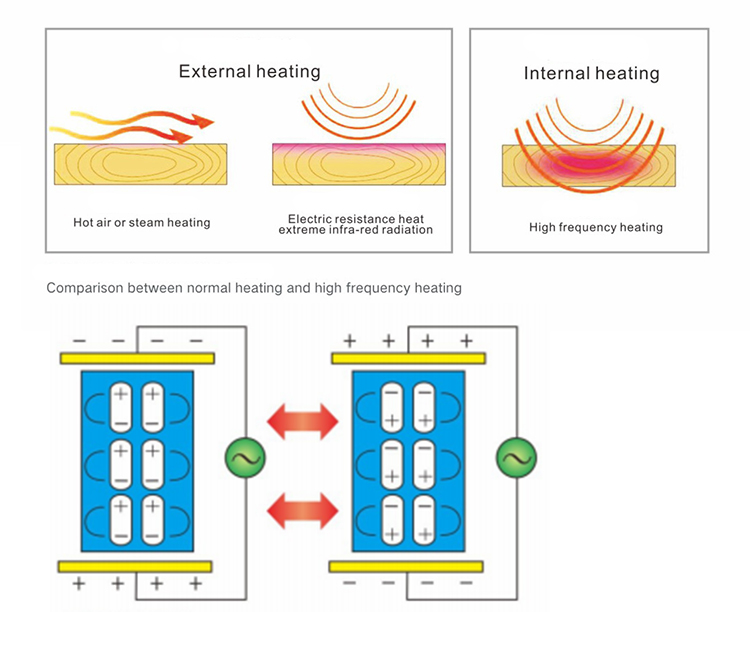

Natural air drying and traditional hot air conduction drying methods can easily cause the surface of the wood to crack easily, but the moisture content inside the wood is still high, especially for wood with high hardness or thickness.

3. Different moisture states in wood

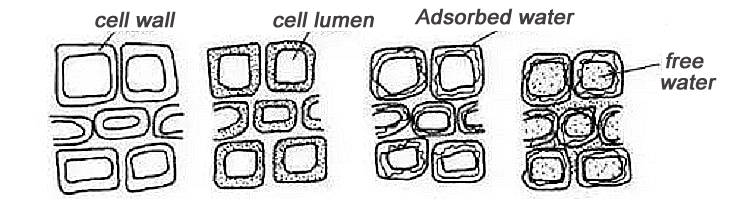

Moisture in wood can be divided into three categories: free water, adsorbed water, and Chemical water.

Free water refers to the water existing in the cell cavity and intercellular space, also known as capillary water; Adsorbed water refers to the water existing between the microfibrils of the cell wall, also known as attached water, adsorbed water; Chemical water refers to the water of special chemical substances in wood, which only accounts for a very small proportion, so it is not used as a discussion point for wood drying.

Free water and adsorbed water are the main moisture in the wood. Free water is closely related to wood density, combustibility, penetrability, etc. Adsorbed water affects wood properties.

The greater force of adsorption of water in wood and the combination of wood, the more heat energy is required to evaporate the water during drying.

2. The Necessity of Grading and Drying Wood

The secondary drying of wood helps to eliminate the moisture content gradient inside the wood, so as to better release the residual tension in the wood and make the finished solid wood furniture more stable.

However, at this process stage, most wood processing enterprises have not clearly regulated the humidity control treatment, which also makes the final effect unsatisfactory. Therefore, in order to fundamentally solve the problem, it is necessary to improve the wood drying process, thus Wood drying classification was proposed.

First of all, the moisture content of the wood must be detected, and the boards with different moisture content can be stacked and used in different grades with the help of the Moisture Tester. The moisture content of the wood can also be calculated according to the weight of the boards to achieve classification, and then the wood moisture content classification technology is applied to wood processing operations. Such graded drying method can not only ensure the drying quality of wood but also improve the drying efficiency and achieve the effect of energy saving and emission reduction.

Improving the dry quality of wood and grading can ensure that the final moisture content of the board is relatively uniform so that problems such as cracking and deformation of wood due to differences in moisture content can be avoided as much as possible. At the same time, such wood will reduce the defects of mechanized batch processing to minimize.

Shorten the drying cycle of wood compared with other wood drying methods, graded drying sets corresponding standards due to the different moisture content of wood, which can greatly improve the overall drying efficiency of wood.

Energy saving and emission reduction. The evaporation of free water and adsorbed water in wood require different drying standards. Graded drying can be used to dry them in a targeted manner, indirectly reducing energy consumption.

Wood drying and grading is an emerging high-efficiency and energy-saving drying process, which is of great benefit in improving production efficiency and quality, and reducing the costs of wood enterprises.

3. Efficient and Stable High-Frequency Vacuum Drying Technology

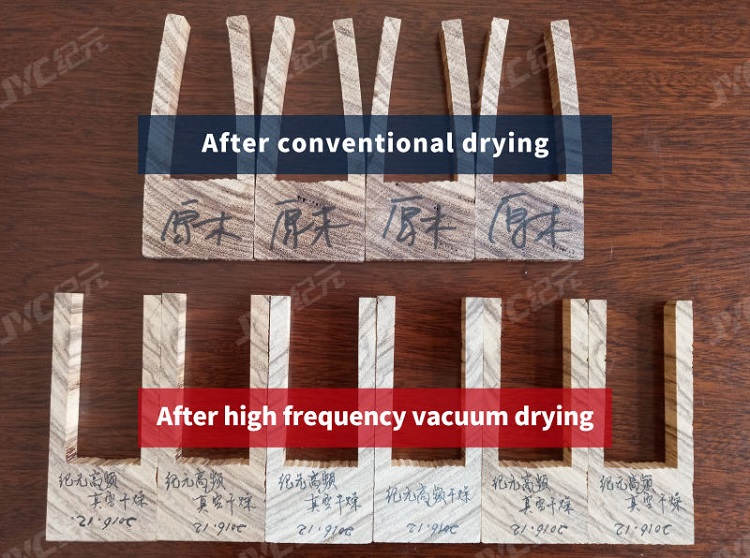

As we all know, in a vacuum environment, the temperature required for water to reach the gasification state will be much lower, supplemented by high-frequency electric field penetrating uniform heating, based on more than 30 years of drying experience of JYC in the application of various tree species, and drying the processing parameters preset on the system, with scientific drying methods such as "Flexible trapezoidal heating technology", realize the intelligence of no need for personnel to be on duty during the entire drying process, in a true sense-so called unattended, ensuring that the plates are dried quickly, and No Discoloration, No Deformation, No Cracking.

High-frequency vacuum drying is a very mature drying technology, which saves time and energy. Its heating principle is to adopt the characteristics of high-frequency penetrating heating technology, which is uniformly heated from the inside to the outside, and combined with the vacuum tank to reduce the temperature required for wood dehydration and balance the moisture content and elimated the tension of the wood. It can greatly reduce the drying time and the impact of fast dehydration on wood quality. It is suitable for drying all kinds of wood, especially for fast drying of high-density hardwood and thick boards.

Normally, if you use the traditional wood drying method, it will take about 1-2 months to reduce the moisture content from 30% to 10%, but if you have JYC high-frequency vacuum wood dryer, you can get high-quality 8-12% wood slabs within 1-2 weeks. And you won't have any more headaches from cracks or uneven moisture levels. JYC high frequency vacuum wood dryer can effectively solve these problems from the root.

Technical characteristics of high frequency drying

Efficient and uniform: high-frequency penetrating heating inside and outside at the same time, uniform heating and fast speed;

Low temperature dehydration: Combined with the vacuum system, the boiling point of water is lowered, and the water is dehydrated quickly under the condition of vacuum and low temperature(below 122 degrees). That is, it balances the moisture content of the wood and ensures that the wood does not change color or crack;

Eliminate tension: Equipped with a pressing system to keep the board under pressure during the drying process, eliminate tension of the wood, and the wood is not easy to deform;

Kill worms and bacteria: high-frequency electric field can effectively kill insect eggs, worms, bacteria and other harmful organisms in wood;

Environmentally friendly production: Wastewater, waste gas and solid waste that pollute the environment will not be produced during the production process, which meets the national environmental protection standards;

Wide applicability: It is suitable for drying all kinds of wood, and the drying process can be intelligently adjusted according to the species, thickness, density and moisture content of the wood;

The Unique Advantages of JYC High Frequency Vacuum Drying Equipment

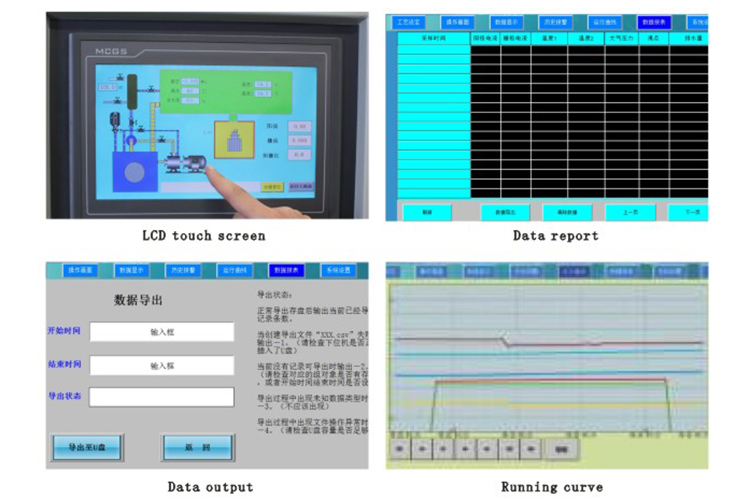

Fully automatic control of the wood drying process, realizing unattended in the true sense.

A variety of drying processes are preset for customers to choose to ensure the quality of wood drying. We have more than 30 years of experience in the production of high-frequency wood machinery.

Equipped with more professional detection devices such as temperature to make the data more accurate and make the product safer and more stable.

The intuitive operation interface on the operation screen, the detailed real-time operation curve is clear at a glance, the accurate operation data supports the digital management system of the customer's factory;

Support remote assistance to realize remote maintenance and system upgrade.

The tank body is all forged with stainless steel, which is durable and minimizes the impact of heat corrosion and wood chemicals on the tank, thus ensuring long-term stable quality of wood drying process.

When drying wood, we should pay more attention to the maintenance of wood strength performance and dimensions without damaging its original characteristics, in addition to the reduction of the moisture content.

Drying methods that damage or degrade wood quality may deviate from our original goals. It is essential to dry wood prudently and gently according to its properties.

You are welcome to contact JYC at any time, and we are honored to discuss with you more industrialization issues such as wood drying.