No cracking, no discoloration, no warping wood rapid drying technology

2023-05-16 17:33We all know wood has been used in our homes and offices for a long time. Although boards and metal boards of various materials have emerged one after another in recent years, such as plywood, particle board and metal multi-layer laminated wood boards, etc., solid wood boards have always occupied the mainstream position in the market, because pure solid wood furniture retains more natural beauty,and more economical and practical.

Many home furniture companies pay too much attention to polishing, painting, modeling, etc., which affect the appearance of the early sales, but often neglect the frequent after-sales problems caused by non-standard processing in the early stage, especially now that many companies' products are sold overseas. Among them, the biggest impact is the after-sales problems such as wood cracking and warping caused by "unbalanced moisture content", which has a great impact on the brand promotion of the company and the repurchase rate of customers.

1. The necessity of wood drying processing

1.1 Ensure that the panels of finished furniture do not shrink

When the moisture content of the wood is lower than 30%, the wood begins to shrink obviously. The shrinkage range varies with the tree species, but generally the shrinkage width is 5-10%, and the shrinkage thickness is 3-6%. Wood that has not been dried, after being made into a product, is prone to shrinkage and lead to cracking at the joints of the furniture and deformation of the fixing parts;

1.2 Reduce internal stress and ensure the stability of the finished plate

Because the wood itself has a moisture content gradient, that is, the moisture content is not balanced. If it is not dried scientifically, affected by regular seasonal temperature and humidity changes, the board is very prone to "water absorption irregular expansion" or "water loss irregular shrinkage", thus causing irreversible bad situations such as cracking;

1.3 Prevent wood discoloration, rot and insects caused by insect eggs and fungi

Most insects need more than 10% moisture to survive, such as some termites and mealy beetles, and eliminating excess moisture will eliminates the possibility of more fungi and insects clinging to the board and do damage, of course , if high-frequency vacuum drying technology is used, these pest problems can be completely solved;

1.4 Let the board not affect the effect of paint or other finishing treatments

If the moisture content of the board is too high, it is easy to cause blistering and peeling of the decorative materials on the surface of the board, such as paint, PVC, veneer, etc., which greatly affects the aesthetics of the product.

2. The necessity of balancing the moisture content of wood

When wood is placed in a certain temperature and humidity environment for a long time, its moisture content will tend to an equilibrium value, which is called the equilibrium moisture content of the environment. When the moisture content of wood is lower than the equilibrium moisture content of the environment, the wood will absorb moisture and expand, otherwise, it will shrink when it dehumidifies.

The equilibrium moisture content of wood is affected by atmospheric humidity and varies from region to region. The northern region is about 12%, the southern region is about 18%. The moisture content of wood such as furniture, doors and windows, and interior decoration must be dried below the equilibrium moisture content of storage and sales areas, otherwise cracking and warping problems will easily occur.

To sum up, the moisture content of the wood itself is not as dry as possible, but should be determined according to the wood equilibrium moisture content in the storage and sales area of the finished furniture.

While drying the wood, it is also necessary to balance the moisture content inside the wood.

As we all know, wood itself has a moisture content gradient. A long time ago, a well-known experimental institution tested a variety of logs of different tree species. The moisture content of each season is different, and the distribution of moisture content on the cross-section of the wood is also different in each season. The moisture content of logs decreases radially from the pith of the tree to the outside, and the average moisture content of the planks located near the pith of the tree is about 12.2% higher than that of the planks near the bark. Of course, this is also related to the density of the wood. High-density wood boards accumulate less water than low-density wood boards. Furthermore, the value of the moisture content gradient also varies with the seasons, about 19.51% in spring, about 17.18% in winter, and the smallest about 4.66% in autumn.

The mainstream wood drying methods on the market, except the high-frequency wood vacuum drying method, other methods will increase the span value of the "moisture content gradient" of wood, especially on thick board or hardwood.

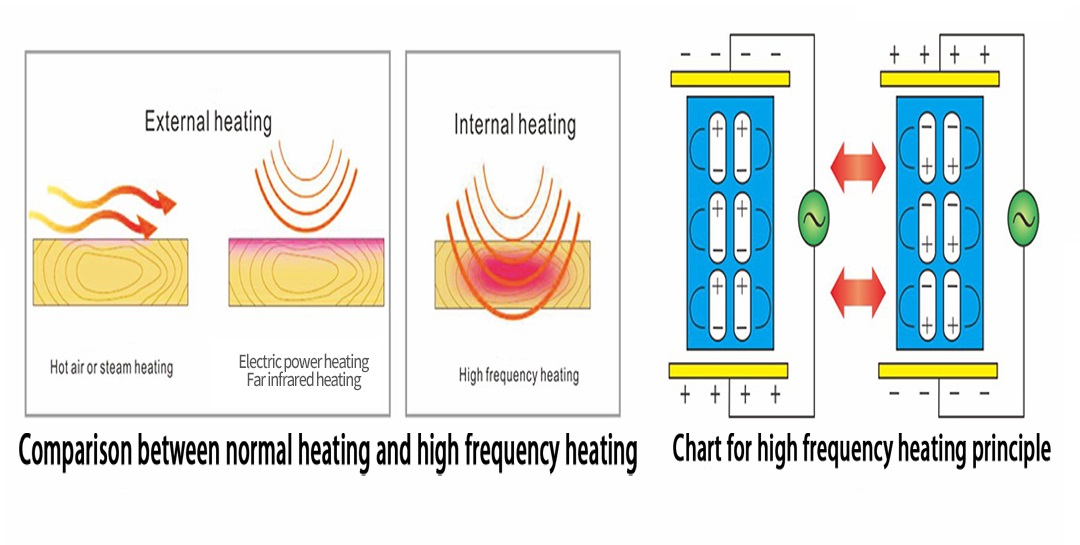

As mentioned above, the moisture content of logs decreases from pith to bark. With the traditional conduction heating technology, the wood is dried by conducting heat from the outside to the inside, such as natural air drying, hot oil, superheated steam, etc. If these drying methods are used for drying logs or over-thick wood , it will easily cause the internal moisture content to remain high, but the moisture content of the wood surface will decrease, so that the span value of the internal moisture content gradient of the wood will rise instead of fall, making the wood more unstable.

However, if the high-frequency drying technology is adopted, the method of penetrating synchronous and uniform heating inside and outside, combined with vacuum technology, under the low temperature state in the vacuum, the moisture can flow out of the wood more quickly and smoothly. Using high-frequency vacuum dryer technology, while drying the wood quickly and safely, it can also keep the moisture content inside the wood in a relatively balanced state, which greatly improves the stability of the wood, whether it is continued storage or processed into furniture.

3. JYC high-frequency vacuum dryer without discoloration, warping and cracking

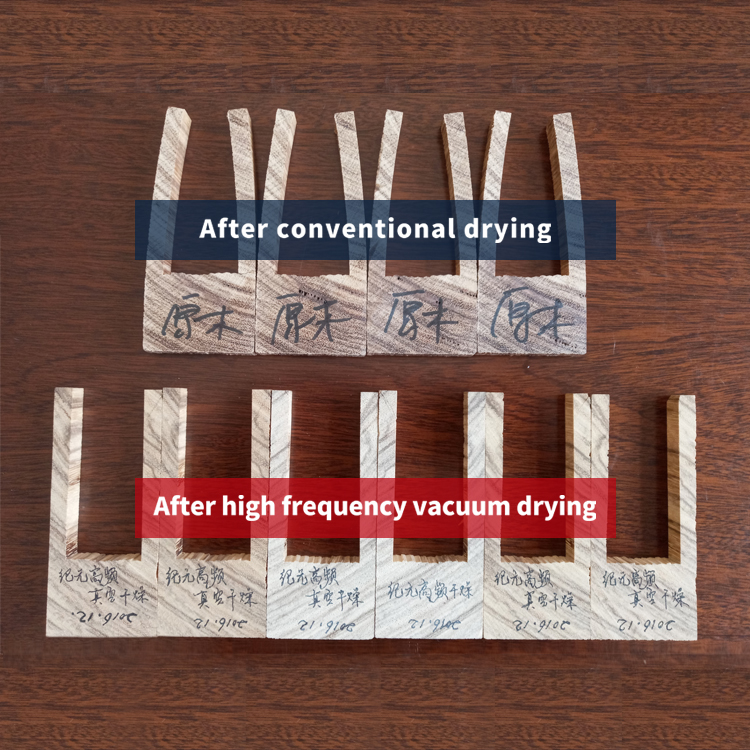

Remarks: The pictures above are the results of wood experiments using conventional drying methods and JYC high-frequency vacuum drying technology

3.1 Advantages of JYC high-frequency vacuum drying technology

3.1.1 Efficient: The high-frequency electric field ignores the thickness of the wood, and heats the moisture in the wood both inside and outside, so that the heating is more uniform and faster;

3.1.2 Stable quality: combined with the vacuum hypoxic system, the boiling point of water is lowered, that is, the moisture content of the wood is balanced and the wood does not change color and crack;

3.1.3 Stress relief: Equipped with a stainless steel pressing plate, the wood board is under pressure during the drying process, and the wood is not easy to warp and deform;

3.1.4 Insecticidal and bactericidal effect: high-frequency electric field can quickly and completely kill insect eggs, worms, mold, etc. in wood;

3.1.5 Environmentally friendly production: The insecticidal effect of the high-frequency electric field eliminates the problems of gas emissions caused by traditional chemical insecticidal methods, and the entire drying process does not produce "waste water, waste gas, organic waste", which meets the standards of environmentally friendly production ;

3.1.6 Wide applicability: They can meet the drying needs of all common wood types and thicknesses, and can intelligently adjust the drying process according to wood thickness, density, moisture content, etc.;

3.2 Features of JYC High Frequency Vacuum Dryer

3.2.1 Fully automatic control of the wood drying process, realize truly "unattended";

3.2.2 After more than 30 years of technical experience accumulation, a variety of drying process parameters are preset to ensure fast and safe wood drying effect;

3.2.3 Multiple sensing and detection devices to ensure the safety and stability of the equipment;

3.2.4 Support remote assistance to realize remote maintenance and system upgrade.

Choose JYC high-frequency wood vacuum dryer to avoid after-sales problems caused by wood moisture content gradient and make wood products more stable. JYC high-frequency wood vacuum drying technology allows wood to dry without cracking, discoloration, or warping, which let the yield rate get higher.