Solid Wood Door Automatic Assembly Production Line

High frequency wooden door assembly line solutions can be designed to customers' requirements. Conventionally it has 5 sections, which can achieve ONE MINUTE ONE DOOR, PASS-THROUGH PROCESSING.

- JYC

- China

- 40 Days

- 200 Set per year

- Information

HF Solid Wood Door Automatic Assembly Production Line

Details

JYC Full automatic Wooden door assembly line solution suitable for fast assembly of wood frames such as solid wood doors, paint-free doors, laminated doors, wardrobe doors, etc. Full automatic control, only needs 1 worker to operate, high-efficiency assembly wooden door.

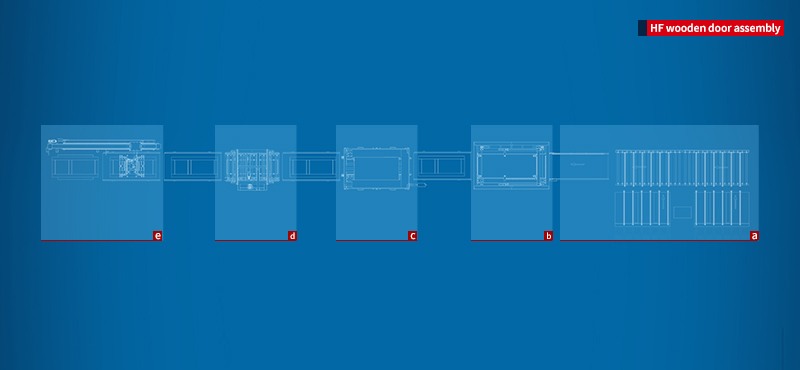

The process of JYC high frequency wooden door assembly line solution:

a. Pre-assembled process section: Automatically flip and send to the assembly line.

b. Pre-assembly process section: The assembled wooden door will be pressed and sawed to ensure the tight joining of the doors.

c. HF door assembly process section: The wooden door's glue can be cured quickly after HF heating and assembly.

d. Auto flipping process section: Clean glue spills from wooden doors and ensure the surface is clean.

e. Auto palletizing process section: Assembled wooden doors will be automatically palletized by the gantry.

Technical Specification

| Model | GZX-1 |

| Capacity output | 480pcs/8h |

| Staffing | 1 worker |

| HF Power | 10KW/20KW |

| Processing Size | 2500*1100mm |

| Process Flow | Full Automatic Production Solution |

We can provide professional suggestions and customized services. Welcome to inquiry!