- Home

- >

- News

- >

- Industry News

- >

News

Solid wood material preparation is an extremely important front-end task in home furnishing manufacturing production.

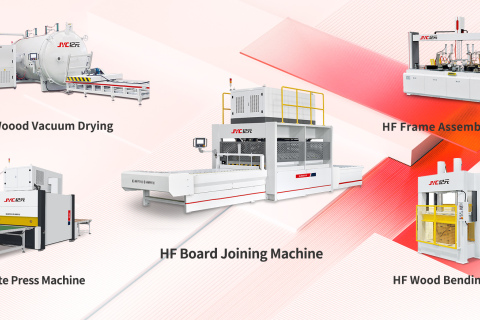

In furniture manufacturing, the front-end solid wood preparation primarily encompasses key processes such as drying, cutting (finger jointing), and panel assembly, directly impacting raw material utilization, subsequent processing efficiency, and the final product quality. However, amidst the current trend of automation upgrades, solid wood preparation still faces numerous challenges in efficiency and quality.

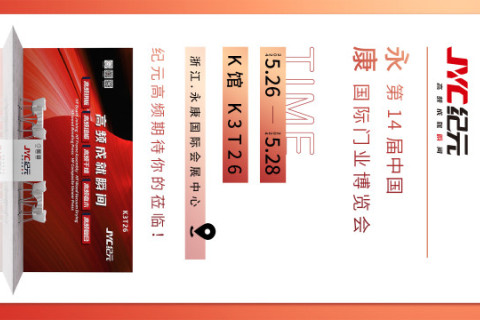

JYC Participates in the 14th China Yongkang International Door Industry Expo

2024 China International Furniture Fair (TianJin)

These situations will happen, the same one wood log, someplace with high moist content but someplace with low moist content.

Some will misunderstand our high frequency thin wood board joining machine to veneer sewing machine.

As we know, there’s a long history of wood application in homes and offices.

Wooden box clamps and high frequency wood box assembly machines serve similar purposes in woodworking, but they differ significantly in their operation, efficiency, cost, and application.

Multi-layer solid wood, also known as engineered wood or multi-ply wood, is a type of wood product composed of multiple layers of wood veneers or plies that are glued together.