- Home

- >

News

Solid wood material preparation is an extremely important front-end task in home furnishing manufacturing production.

In furniture manufacturing, the front-end solid wood preparation primarily encompasses key processes such as drying, cutting (finger jointing), and panel assembly, directly impacting raw material utilization, subsequent processing efficiency, and the final product quality. However, amidst the current trend of automation upgrades, solid wood preparation still faces numerous challenges in efficiency and quality.

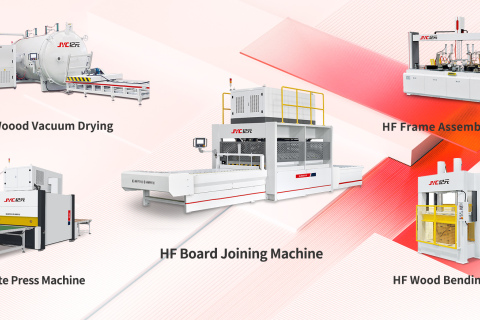

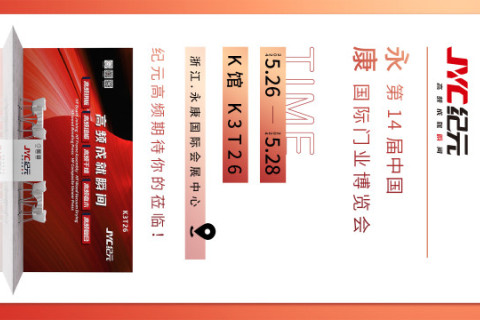

JYC Participates in the 14th China Yongkang International Door Industry Expo

You must have seen these wood products in life. Beautiful and elegant wooden cabinets, wooden boxes, and wooden frames.

A good environment can make manufacturing better!

Wooden box clamps and high frequency wood box assembly machines serve similar purposes in woodworking, but they differ significantly in their operation, efficiency, cost, and application.

What can increase the assembly efficiency?

Solid wood doors are famous for their natural texture.

The assembly of wooden frames is mostly done by manual nailing or manual gluing. Machine assisted assembly can greatly improve efficiency.

As a leading company in the field of high frequency application technology, JYC High Frequency will continue to lead this wave of home manufacturing efficiency revolution with its solid technological accumulation.

Let's come with us to visit our client's factory which produces solid wood doors!